Barite Powder Processing Plant Working Site In Sichuan

Machine introduction :

HGM Three-ring four-ring micro powder grinding mill

Applications: Calcium carbonate crushing, gypsum crushing, power plant desulfurization, non-metallic mineral milling, coal powder preparation, etc.

Materials: limestone, calcite, dolomite, barite, talc, gypsum, quartz, bentonite, etc.

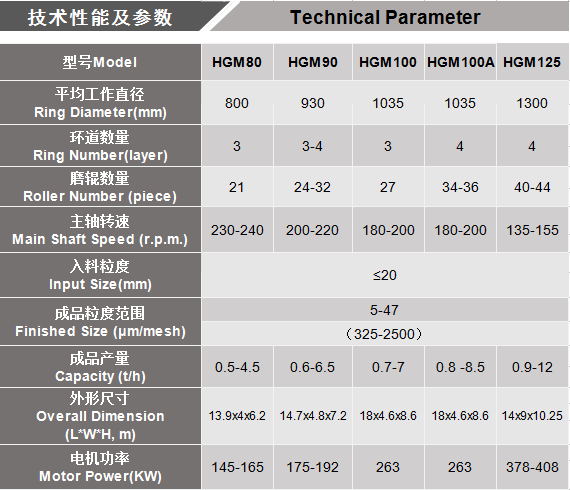

Feed particle size: ≤20mm Production: 0.5-12T/H

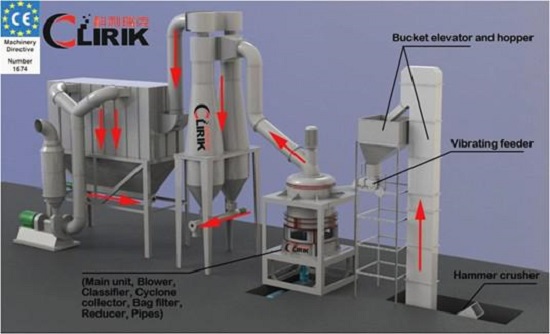

HGM three/ four ring roller micro grinding mill (medium speed micro grinding mill) draws on Swedish grinding technology, based on the development trend and demand of domestic mill market, a new equipment designed for users of ultra-fine powder processing. It is mainly suitable for non-flammable and explosive materials with a Mohs hardness of 7 or less and a humidity of 6% or less, such as barite, calcite, calcium carbonate, dolomite and talc.

Working principle

Working site

Sichuan Barite Powder Processing Plant

Mill: HGM800 three-ring micro powder grinding mill, installed power 118.5KW

Production status

[Materials and Finished Products]: Processing barite, various specifications between 800-2000 mesh

[Production]: 30 tons / day

[Customer evaluation]: As an old customer of Clirik, we are very satisfied with this equipment. Under the same fineness and power consumption of the finished product, the investment cost is lower than that of the jet mill, the payback period is short, but the output is more than 45%, and the loss is Low, at the same time low equipment loss, durable, Clirik is a reassuring brand.

Recommended Products

1. 0-3mm Hammer Mill;

2. 50-325 mesh YGM Raymond Mill;

3. 200-3000 mesh HGM Ultra Fine Mill;

4. 325-3000 mesh CLUM Vertical Roller Mill (2µm>50% ).

Performance characteristics

Safe and reliableThere are no rolling bearings and screws in the grinding chamber, which avoids the problem that the bearing is vulnerable and the screw is loose and the equipment is destroyed. The equipment adopts pulse dust collector, equipped with silencer and silencer room, which reduces dust and noise pollution and has good environmental protection effect.Low investment efficiencyUnder the same fineness and power consumption of the finished product, the investment cost is lower than that of the jet mill, and the recovery period is short, but the output is higher than 45%.Low loss and high finenessThe wearing parts are made of wear-resistant materials, the service life is more than one year, and the final fineness of the finished product can reach D97≤5μm at one time.

For product information and pricing, Chat with sales agent:

Chat