Table of Contents

- 1 Product overview of barite micro powder grinding mill

- 2 Product specifications of barite micro powder grinding mill

- 3 Working principle of barite micro powder grinding mill

- 4 Product featuers of barite micro powder grinding mill

- 5 Customer Case of barite micro powder grinding mill

- 6 Other Products offered

- 7 Manufacturer introduction of barite powder grinding mill

- 8 FAQ

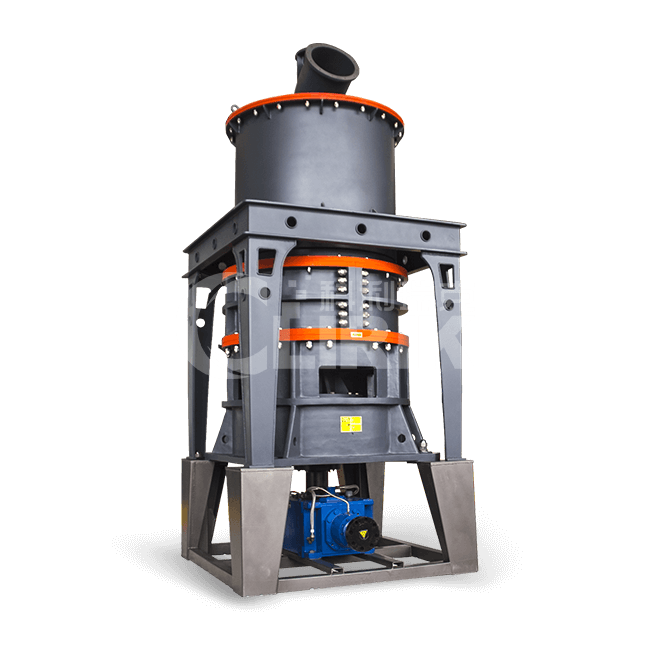

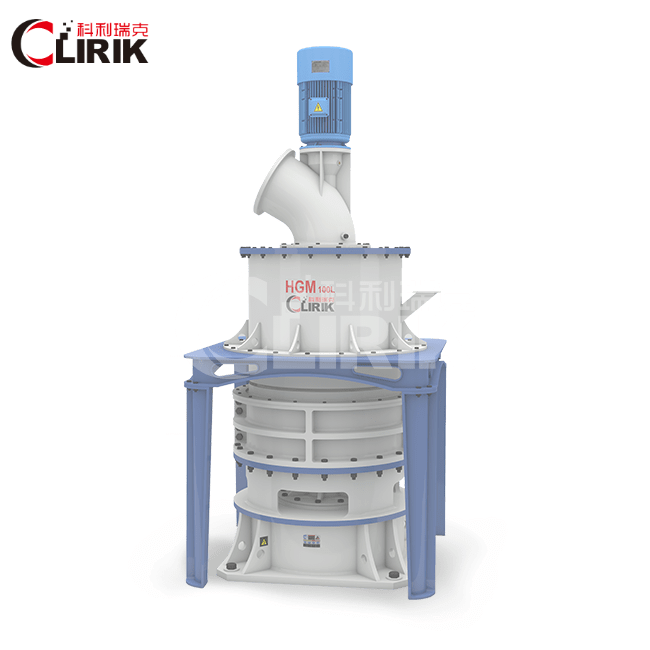

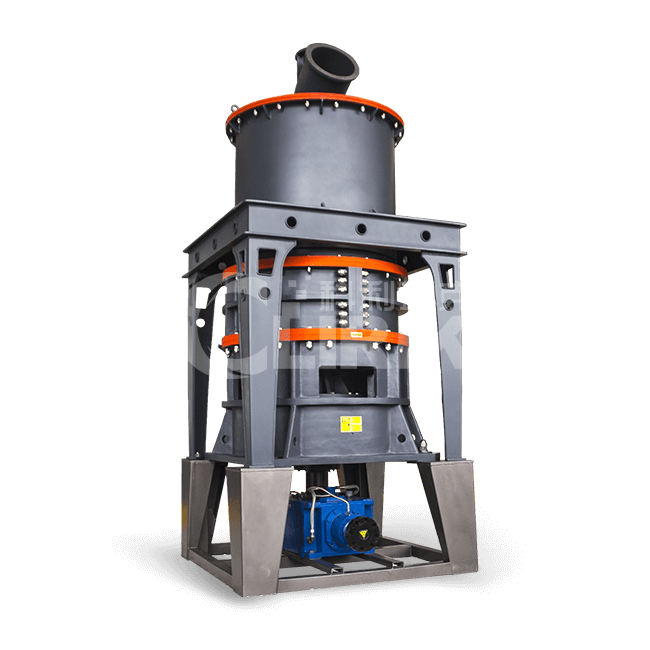

Product overview of barite micro powder grinding mill

Barite micro powder grinding mill is a new type of mill developed by Clirik by virtue of its own technology research and development ability, drawing on the advantages of similar products at home and abroad. A mill with comprehensive crushing properties such as grind, grinding and impact.

Barite micro powder grinding mill have the characteristics of large output, low energy consumption, long service life and easy maintenance. This is a perfect choice for customers who like a high return on investment.

The barite micro powder grinding mill can grind non-metallic ore material. Such as calcite, chalk and limestone, dolomite, barite, bentonite, talc, mica, magnesium stone, illite and pyrophyllite, vermiculite, sepiolite, attapulgite, pale spot, barite, alum stone, black lead, fluorite, phosphate, potash, pumice, etc.More than 1000 kinds of moh‘s hardness under level 6 not inflammable, explosive brittle material.

Types of Barite micro powder grinding mill, vertical powder mill, powder making machine:

– – Five models: HGM80, HGM90, HGM100, HGM125, and HGM1680.

– – Finished powder fineness: 325 mesh ~3000 mesh, 5-74 micron

– – The capacity (ton/hour): 0.4T/H – 30T/H

Product specifications of barite micro powder grinding mill

Specifications 1

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

Specifications 2

| Unit kw | HGM80 | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Main unit | 75 | 2*45 | 132-150 | 132-150 | 185-200 | 315 |

| Classifier | 18.5 | 18.5-30 | 30-37 | 30-37 | 75 | 132 |

| Blower | 45 | 55 | 75 | 75 | 2*45-2*55 | 2*75-2*90 |

| Crusher | 18.5 | 18.5 | 18.5 | 18.5 | 45 | 75 |

| Bucket Elevator | 3 | 3 | 4 | 4 | 4 | 7.5 |

| Belt Conveyor Feeder | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2 |

| Discharging Valve | 2*0.75 | 1.1 | 1.1 | 1.1 | 1.5 | 2*1.5 |

| Air Compressor | 11 | 15 | 22 | 22 | 37 | 55 |

Working principle of barite micro powder grinding mill

Barite micro powder grinding mill mainly consists of main unit, classifier, powder collector, dust cleaner, blower, muffler, sound-proof room, crusher, bucket elevator, storage hopper, and vibrating feeder.

After being crushed by a hammer crusher, the large materials become small ones and are sent to a storage hopper by elevator.

And then evenly sent to the upper distribution plate of the turnplate by vibrating feeder and sloping feeding pipe.

When the superfine powder grinding mill is at work, the main bearing and each dial are driven by the electromotor of the main equipment through a reducer. And all the grinding rollers are rolling in the ring channels driving by dial through plunger.

You can learn how the barite micro powder grinding mill works by watching the video.

The materials are driven to the edge of the turn plate by the centrifugal force and fall down into the grinding chambers. And the materials are repeatedly pressed, crushed, and ground by the rollers in grinding chambers. Then the materials fall into multiple layers and to be crushed and ground continuously to micro powder.

The high-pressure air blower constantly inhales air within the fine grinding mill. In turn, the airflow with crushed materials is brought to the classifier, whose high-speed impeller will screen the airflow. The unqualified particle size will fall and return to the mill for being reground, while the qualified particle size mixed with air will go into the cyclone powder collector.

Most of the qualified powders will fall and exit from the discharging valve at the bottom. A small proportion of the fine powders, with airflow, moves to the dust cleaner and clings to the surface of the filter bags.

At the same time, the fine powders clinging to the surface fall down by the sudden vibration of the filter bags, which is caused by the instantly ejected high-pressure gas controlled by the pulse valve.

The materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed. In addition, filtered clean air will be emitted from the air outlet of the muffler in the end.

Product featuers of barite micro powder grinding mill

1. Meet client’s requirements for different fineness powder, finished powder fineness is adjustable and at stable quality.

2. Built-in high efficiency classifier, higher classification accuracy, better classification effect.

3. Use new upgraded main machine transmission mechanism, it has higher output, lower energy-consumption, easy maintenance.

4. All main wear parts use quality abrasion-resisting alloy steel, and have a longer working life.

5. The whole system works under negative pressure without dust emission, no coarse particle air pollution, more environment-friendly, higher fineness powder recovery.

6. Smart PLC controlled, remote centralized control, one-button easy operation, intelligent control of feeding material, all the above ensure grinding mill operation stable and high output.

7. The whole grinding mill system with a compact structure could save factory space, with a lower foundation construction cost, it’s a cost-effective investment. High quality Barite micro powder grinding mill for barite powder production line

Customer Case of barite micro powder grinding mill

The following picture is the barite micro powder grinding mill site of our previous customers. If you want more information, you can click here to contact our customer service staff.

Other Products offered

In addition to HGM series barite micro powder grinding mills, we have other barite mills for your choice.

Manufacturer introduction of barite powder grinding mill

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

What can we do for you?

A.Pre-sale:

1.Equipment sizing assistance based on customer’s demand

2.Assistance in planning the layout of workshop according to customer’s site conditions

3.Assistance in designing and installation of the foundation drawing and process flow diagram based on customer’s demand.

4.Guidance on preparation work.

B. During sale:

1. Strict control of production to ensure product quality

2. Elimination of hidden dangers with strict factory inspection and traceability system.

3. Providing logistics information.

4. Guidance on the preparation of equipment foundation.

5. Guidance for installation and commissioning.

6. Offering professional technical training.

C. After-sale:

1. Guidance on various powder production processes for customers.

2. Periodic follow-up on device usage.

3. Instructions on equipment maintenance.

4. Solution of relevant problems in the shortest time.

5. Timely and efficient replacement of spare parts.

6. Professional and fast equipment maintenance.

FAQ

1. What is barite powder used for?

Barite Powder or barite (BaSO4) is a mineral consisting of barium sulphate. The baryte group consists of baryte, celestine, anglesite and anhydrite. Baryte is generally white or colourless and is the main source of barium. It is widely used in oil, natural gas drilling, mud weighting agents, in the barium chemical industry, packing, construction and other fields.

2. Which mills are used for grinding?

Barite micro powder grinding mills, vertical ultra-fine grinding mill, stirred mills, European version coarse grinding mill, ball mill, jaw crusher, hammer crusher, impact crusher, cone crusher, Roller crusher and so on. specific use of which device to decide according to your needs, you can give us a message consultation.

3. What is the price of a barite powder grinding mill?

Our company has various types of barite powder grinding equipment. The specific price of the machine needs our sales manager to communicate with you.

You can leave your contact information (email or Whatsapp, phone number)

4. Why choose us?

We not only provide customers with high quality barite grinding equipment, but also provide customers with on-site survey, design and production program, product installation, technical personnel training and other one-stop services.

Related Products

Messages

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40