Table of Contents

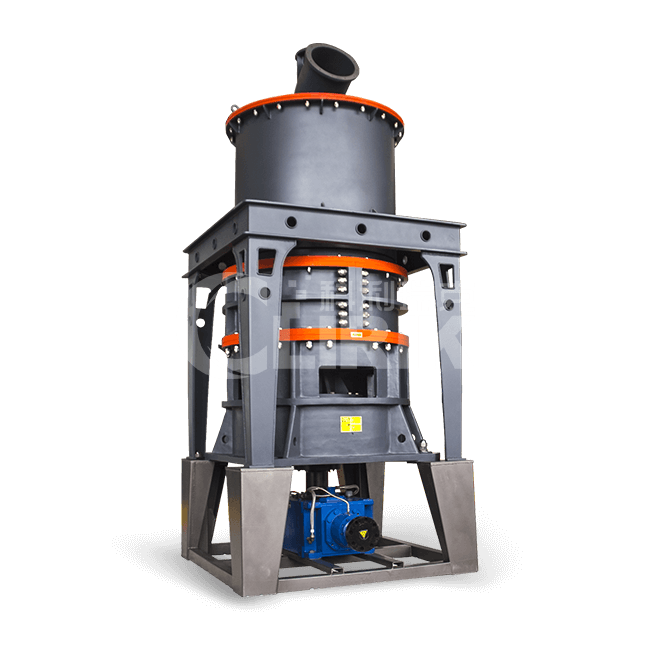

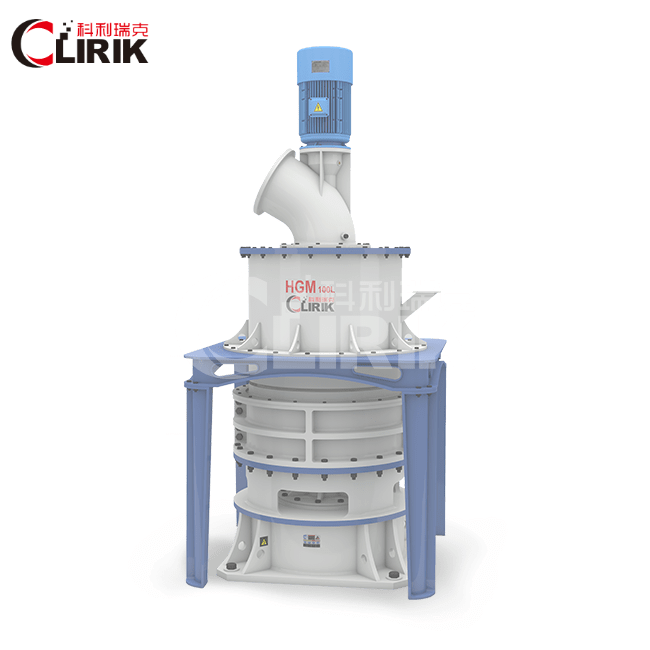

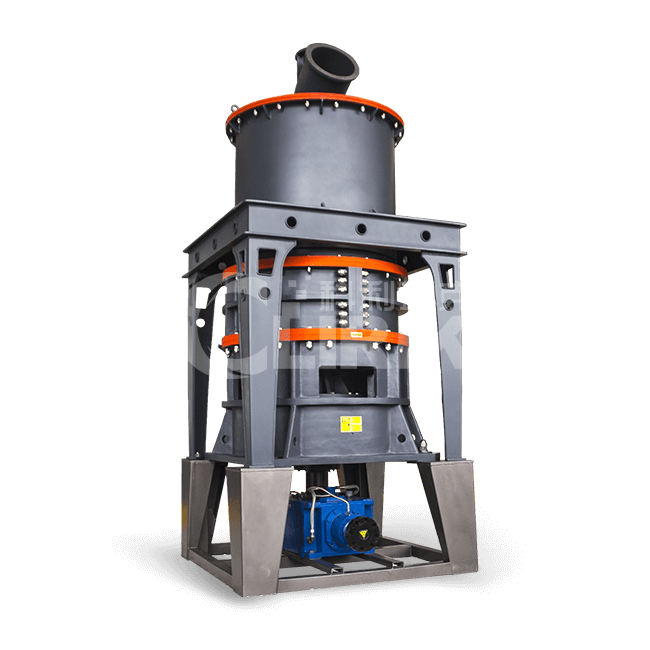

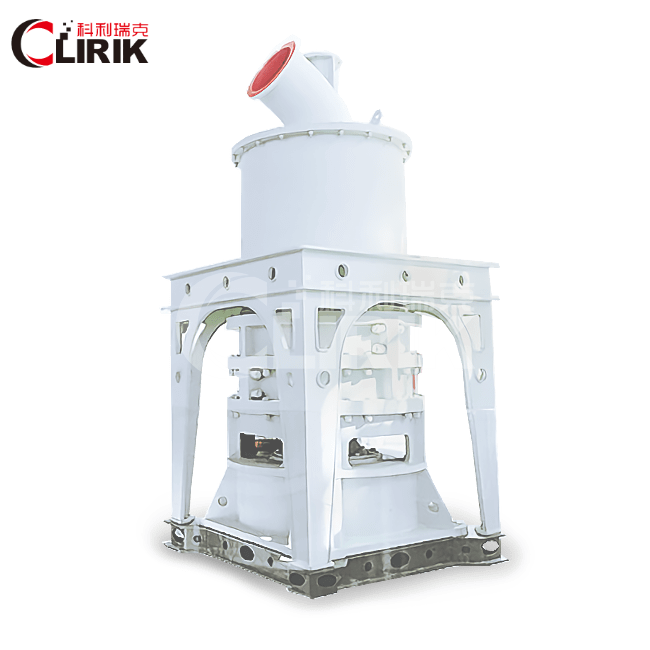

Product introduction of barite superfine powder mill

Barite superfine powder mill is a high-efficiency and energy-saving grinding equipment developed by SHANGHAI CLIRIK MACHINERY CO., LTD This mill can grind 325-3000 mesh powder, which is suitable for grinding barite ore and other non-metallic minerals with Mohs hardness below 7 and humidity within 6%.

The mill has several advantages over traditional grinding mills. Firstly, the equipment has a high efficiency and energy-saving design, which can save up to 30% energy compared with similar products. Secondly, the mill adopts a multi-stage classification system, which can effectively improve the accuracy and efficiency of the powder selection. Thirdly, the mill is equipped with an advanced dust removal system, which can effectively reduce the dust pollution during the grinding process.

Barite superfine powder mill has been widely used in the fields of metallurgy, building materials, chemical industry, mining, highway construction, water conservancy and hydropower, and other industries. It has also been widely used in the grinding and processing of non-metallic minerals such as barite, calcite, talc, and kaolin.

In summary, Barite superfine powder mill is an ideal equipment for grinding barite ore and other non-metallic minerals. With its high efficiency, energy-saving, and advanced dust removal system, it can greatly improve the grinding efficiency and reduce the environmental pollution caused by grinding.

Product advantage of barite superfine powder mill

Barite superfine powder mill is a type of grinding equipment that is designed to process fine and ultrafine powder of barite minerals. Here are some of its advantages:

1. High Efficiency: Barite superfine powder mill has a high efficiency and low energy consumption. The milling process is stable, and the product quality is good. It can effectively improve the grinding efficiency and productivity of the milling process.

2. Wide Range of Applications: The barite superfine powder mill can be used in various industries such as chemical, metallurgical, building materials, mining, and other fields. It is suitable for grinding materials with Mohs hardness below 7 and humidity within 6%, such as barite, calcite, marble, limestone, kaolin, and other non-metallic minerals.

3. High Precision: The equipment is equipped with a high-precision grading system, which can produce products with a particle size of 325-3000 mesh. The finished product has a high precision and uniformity, which can meet the requirements of different industries.

4. Environmental Protection: Barite superfine powder mill adopts a pulse dust collector and muffler to reduce dust pollution and noise. It can effectively reduce the harm to the environment and the health of workers.

5. Easy Maintenance: The equipment has a simple and compact structure, which is easy to maintain and repair. The wearing parts are made of high-quality wear-resistant materials, which can prolong the service life of the equipment and reduce the maintenance cost.

Overall, the barite superfine powder mill has many advantages, which make it an ideal equipment for processing barite minerals and other non-metallic minerals.

Product parameter of barite superfine powder mill

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

Working principle of barite superfine powder mill

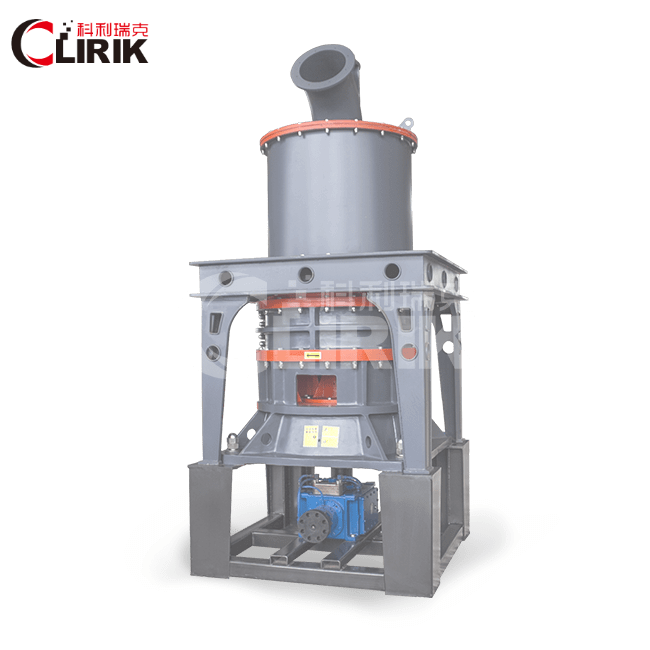

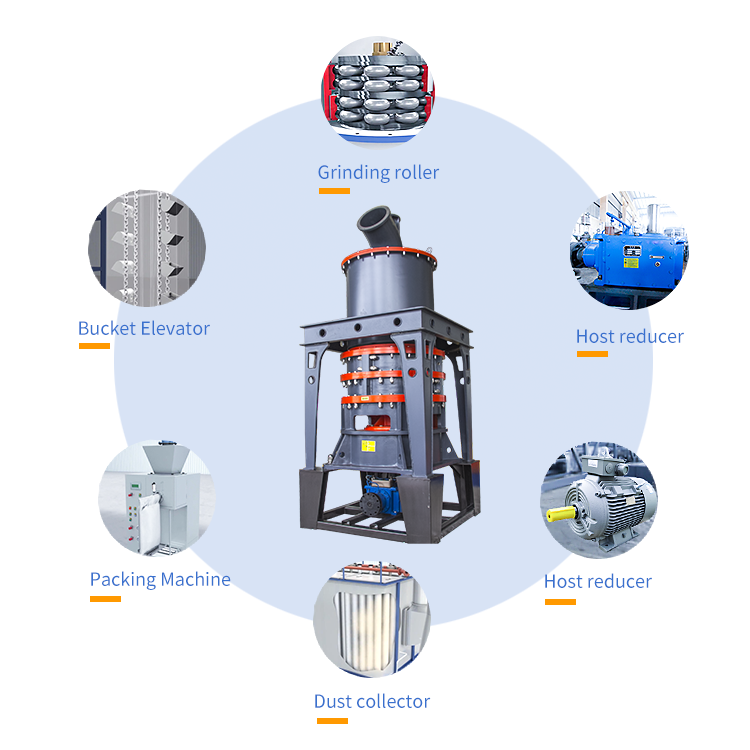

Barite superfine powder mill, also known as barite micro powder grinding mill, is a grinding equipment that is commonly used for grinding non-metallic minerals into fine powder.

The working principle of the mill is that the grinding roller is tightly pressed on the grinding ring under the action of centrifugal force. The material is fed into the mill through the feeding hopper and is ground by the grinding roller and the grinding ring.

The ground material is blown up by the air flow of the blower and sent to the analyzer for classification. The unqualified powder falls back to the grinding chamber for re-grinding, while the qualified powder is collected by the cyclone collector and sent to the finished product bin.

The grinding roller and grinding ring are made of high wear-resistant materials, which can effectively extend the service life of the equipment. The superfine powder mill can achieve high efficiency grinding of various non-metallic minerals with Mohs hardness below 7 and humidity within 6%, such as barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass, and thermal insulation materials, etc.

FAQ

1. Why choose Clirik ?

Clirik is a manufacturer specializing in the manufacture and development of grinding machines. We have high quality products and excellent service team.

2. Is there a warranty service?

Buy our barite superfine powder mill, the main engine is guaranteed for one year free of charge.

We stock a large number of spare parts. We can deliver them to you within about a week of placing your order.

3. How long will it take to deliver?

The goods can be delivered in 10-25 working days after the payment is made.

4.What is the payment method?

L/C, Western Union, D/P, D/A, T/T, MoneyGram, Cash, Alibaba.com Pay.

5. What are the modes of transportation?

By express, by sea, by land, by air.

Related Products

Messages

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40