Table of Contents

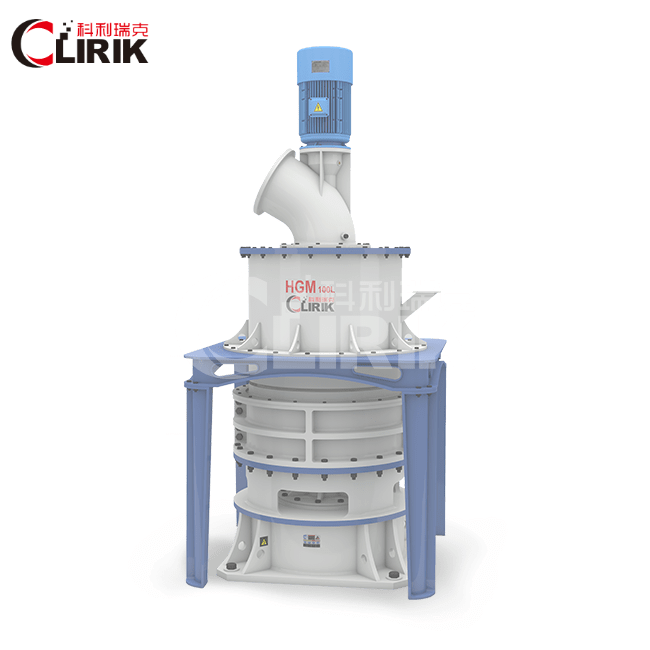

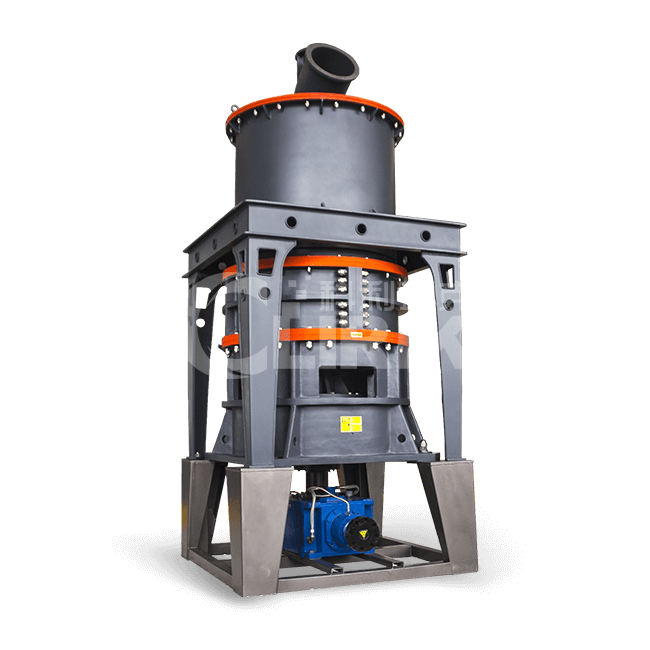

Product Introduction

Barite vertical ring roller mill is a type of industrial equipment used to crush or grind materials into small particles, It is widely used in the fields of metallurgy, building materials, chemical industry, mining, highway construction, water conservancy, and hydropower.

The Barite vertical ring roller mill operates on the principle of material bed comminution. It utilizes a grinding mechanism that includes rollers, grinding plates, and a rotating table.

As the table rotates, the rollers press against the grinding plate, which in turn crushes the material that has been fed into the mill.

The Barite vertical ring roller mill is capable of producing different fineness levels, ranging from coarse to ultrafine, depending on the specific requirements of the application.

It has a high grinding efficiency, low energy consumption, and a relatively small footprint. Additionally, it is easy to operate and maintain, which makes it an ideal choice for many industries.

Overall, the Barite vertical ring roller mill is a reliable and efficient tool for grinding and crushing materials. Its widespread use in various industries attests to its effectiveness and utility.

Working principle

Barite vertical ring roller mill is a type of industrial equipment used to crush or grind materials into small particles. It works by applying high pressure on the material through a set of rollers that rotate around a vertical axis.

The working principle of a Barite vertical ring roller mill can be summarized as follows:

1. Raw materials are fed into the mill through the feeding device. The material is then conveyed to the grinding chamber, where it is crushed or ground by the rollers.

2. As the material is ground, it is transported upwards by the air flow generated by the blower.

3. The classifier separates the fine material from the coarse material. The fine material is collected in the dust collector, while the coarse material falls back into the grinding chamber for further grinding.

4. The finished product is collected in the discharge device.

The key components of a Barite vertical ring roller mill include the grinding rollers, grinding table, hydraulic system, and air blower. The grinding rollers are responsible for crushing or grinding the material.

While the grinding table provides support and acts as a surface for the rollers to grind against. The hydraulic system provides the necessary pressure to the rollers, while the air blower generates the air flow needed to transport the

material.

Product Characteristics

Barite vertical ring roller mill is a type of grinding equipment that is commonly used in the processing of barite minerals. Some of the characteristics of this barite vertical ring roller mill include:

High grinding efficiency

The vertical ring roller mill is designed to have a high grinding efficiency, which means that it can produce a large amount of material in a short period of time.

Low energy consumption

The mill is designed to operate with low energy consumption, which helps to reduce the overall operational costs.

Advanced grinding technology

The mill uses advanced grinding technology, which helps to ensure that the barite mineral is finely ground to the desired particle size.

Stable operation

The vertical ring roller mill is designed to operate in a stable manner, which helps to minimize the risk of equipment failure and downtime.

Easy maintenance

The mill is designed to be easy to maintain, with simple and straightforward maintenance procedures that can be carried out by trained personnel.

Environmental friendliness

The mill is designed to be environmentally friendly, with features such as low noise and low dust emissions.

Product Maintenance

To maintain a barite vertical ring roller mill, you should follow these general guidelines:

1. Regularly inspect the barite vertical ring roller mill’s components, such as the grinding roller and ring, the air blower, the oil pump, and the reducer. Look for signs of wear or damage and replace any parts that are worn out or broken.

2. Check the oil level and quality in the barite vertical ring roller mill’s lubrication system. Make sure to change the oil regularly according to the manufacturer’s recommendations.

3. Keep the barite vertical powder mill’s air blower and dust collector clean and free of debris. Regularly check the filter bag and replace it if it is clogged or damaged.

4. Check the mill’s electrical system, including the wiring, switches, and controls. Ensure that all connections are secure and that the electrical components are in good condition.

5. Keep the mill’s working area clean and free of dust and debris. This will help prevent damage to the barite powder mill and ensure that it operates efficiently.

6. Schedule regular maintenance checks and inspections by a qualified technician or service provider. They can identify any potential issues early on and perform preventative maintenance to keep the barite micro powder grinding mill operating smoothly.

By following these guidelines, you can help ensure that your barite vertical ring roller mill operates smoothly and efficiently for years to come.

Product Parameter

There are 7 models of HGM series barite vertical ring roller mill for you to choose from, if there is a mill you are interested in, you can click here to consult us. Our sales manager will get in touch with you later.

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

Related Products

Messages

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40