Table of Contents

Product Overview

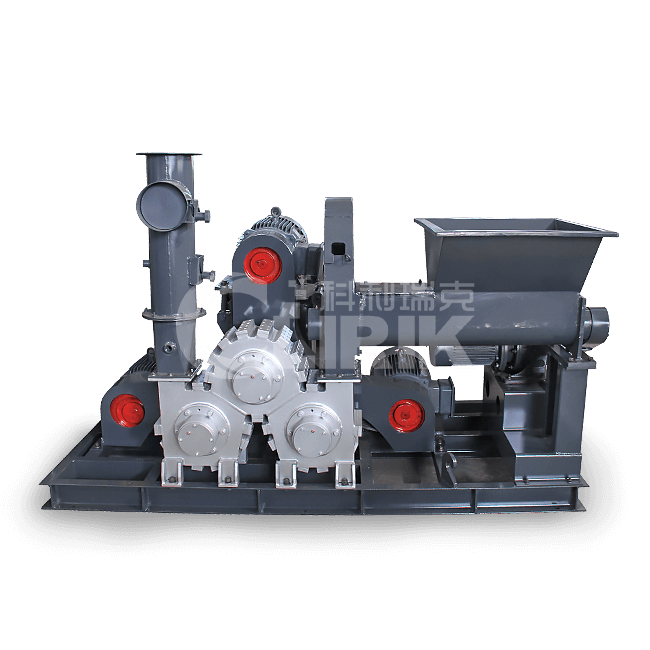

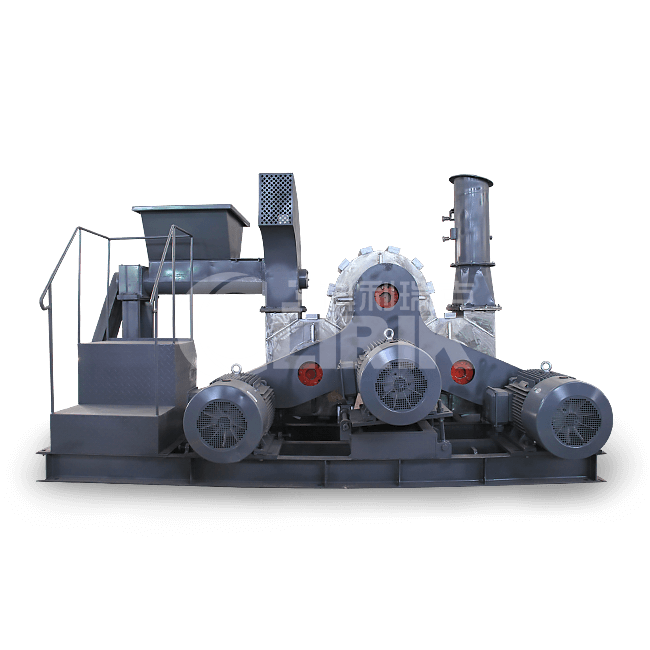

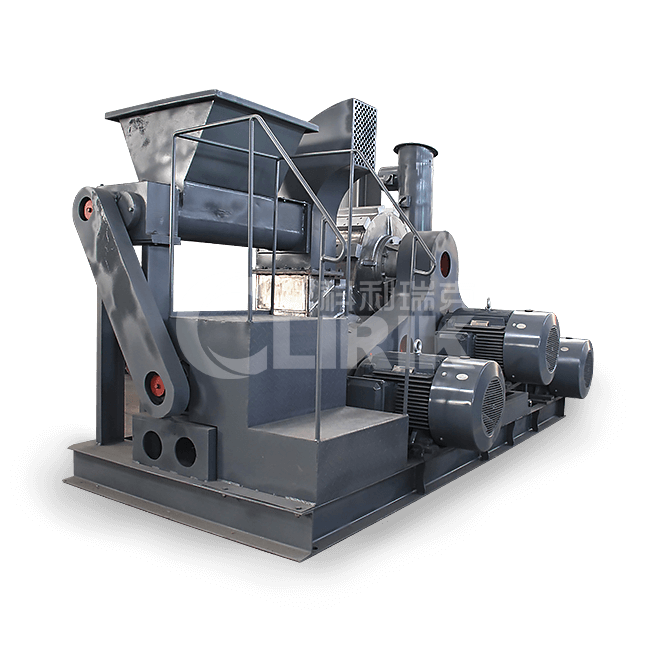

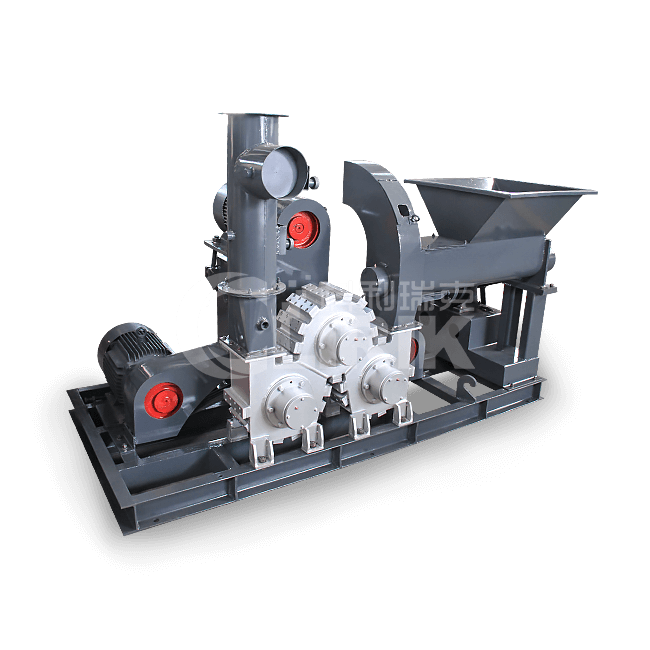

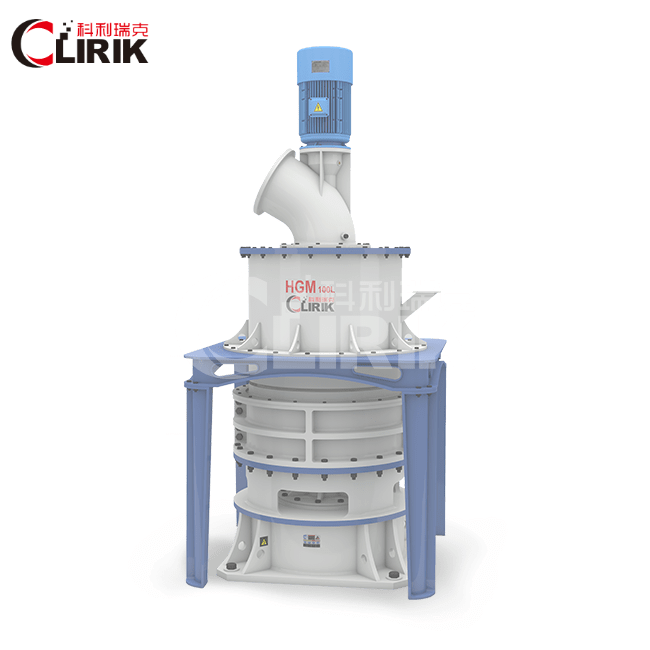

CLG Series Powder Surface Coating Machine

Model : CLG Series

Capacity : 40-7000 kg/h

Max feeding size: Optional

Processing ability: 40-7000 kg/h

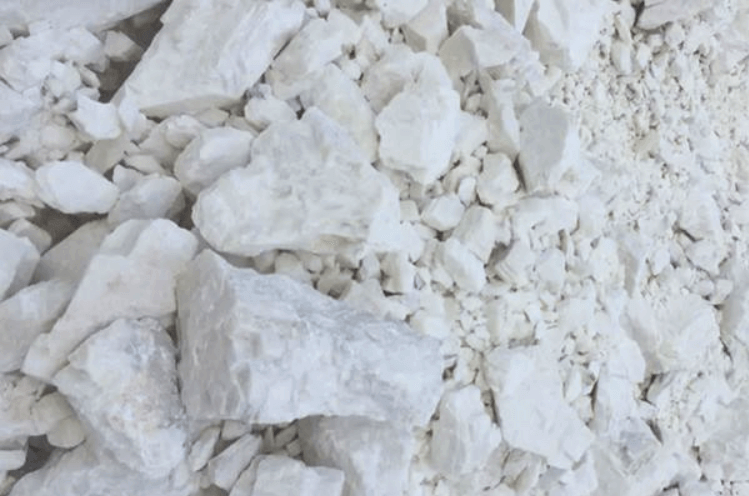

Use Range : Heavy / light calcium carbonate、Kaolin、 Talcum、Wollastonite、 Mica、White carbon black、 Zinc oxide、Alumina、Silicon powder、Graphite…

Application : Pigment、 Plastic、 Rubber、 Adhesive、Macromolecule materials、 High polymer composite、 Functional materials…

Product Parameter

| Model | Main Power | Blower Power | Speed of Shaft | Capacity | Weight | Overall Dimension |

| CLG-200D | 11 kw | 2.2 kw | 5700 r.p.m | 40-150 kg/h | 1 t | 3200*600*2200 mm |

| CLG-3/300 | 3-18.5 kw | 5.5 kw | 4500 r.p.m | 500-1800 kg/h | 3 t | 5800*1800*5600 mm |

| CLG-3/600 | 3-37 kw | 15-22 kw | 2700 r.p.m | 2000-4000 kg/h | 10 t | 11200*3100*6200 mm |

| CLG-3/900 | 3-75 kw | 45 kw | 2000 r.p.m | 4000-7000 kg/h | 20 t | 21000*3800*6500 mm |

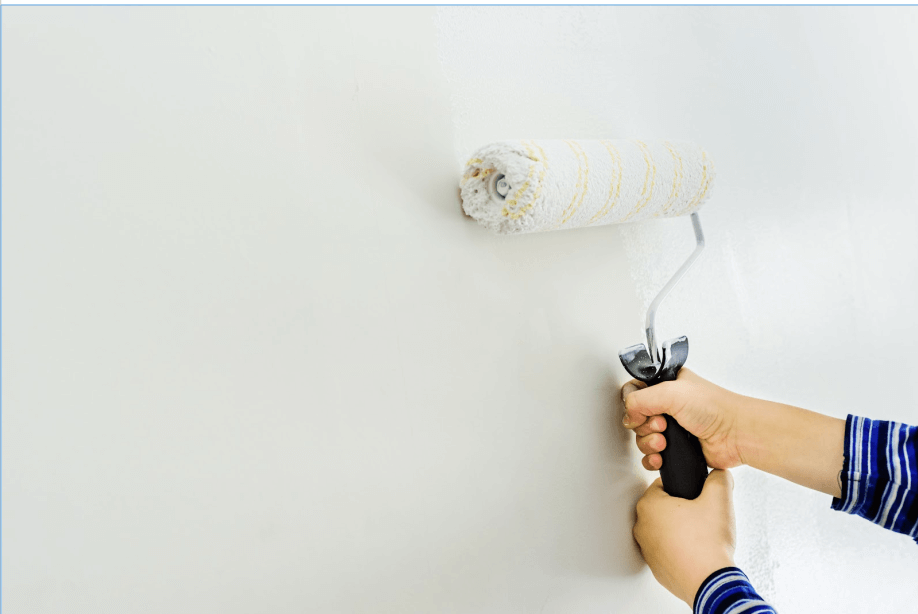

Product Application

A mineral CLG Series Powder Surface Coating Machine is also called a Powder surface coating machine.After dealing with Powder Coating machine, it can not only improve the compatibility of both non-organic mineral stuff and organic high polymer, enhance the binding force of interfaces, rise the mechanical strength and comprehensive ability, but also increase the stuffing ability of powder, save product cost and add a special physical and chemical property to the product to some extent.

CLG Series Powder Surface Coating Machine is widely used in the fields of non-metal stuffing like pigment, plastic, rubber, adhesive, macromolecule materials, high polymer composite, functional materials, and dope industries. It is an outcome of the development of new and high technology nowadays.

With special chamber design and the function of modification and depolymerization, CLG Series Powder Surface Coating Machine is applicable to modifying various materials. It can reach excellent surface modifications for such materials as heavy/light calcium carbonate, kaolin, talcum, wollastonite, mica, white carbon black, zinc oxide, alumina, silicon powder, graphite, magnesium-hydroxide bariumcarb, illite claystone, and pyrophylite, hexagonite and etc.

Product Advantage

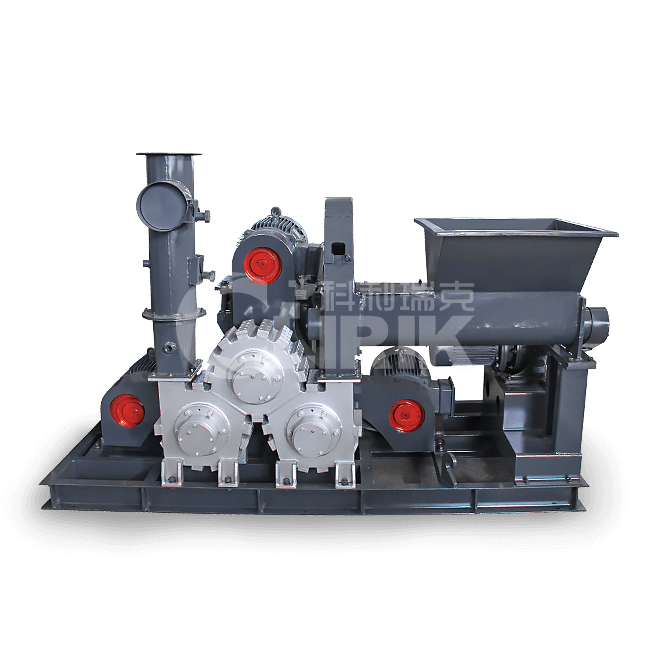

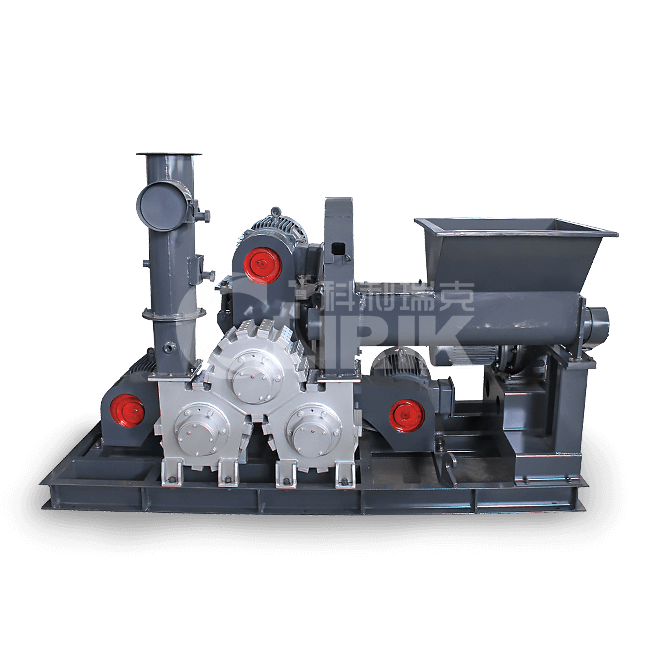

A. Hopper: Materials enter into hopper from silo or bags. Humidity of feeding materials should be less than 0.5%

B. Conveying device: With double screws and adjustable speed to ensure the stability of material flow

C. Agent adding system with temperature control: Automatic Temp. Control, free setting of melting temperature, suitable for various modifying agents in both solid and liquid form.

D. Main machine: Consisting of 3 modifying rollers in triangle form, compact design, high efficiency and stable running.

E. Cyclone dust collector: Diffusion type.

F. Impulse type bag dust collector: New generation pleat filter, with the advantage of little space, large filtration area, high dust removal efficiency and easily cleaning.

Working Principle

CLG Series Powder Surface Coating Machine treatment is completed mainly by means of three modifying rollers. The dry powder and dosed agent are put into modifying rollers simultaneously. With high speed rotation, the materials and agent is running in the form of fluidizing vortex. The modification is completed with the heat generated by high speed shearing, colliding and friction among the rotor, stator and the powder.

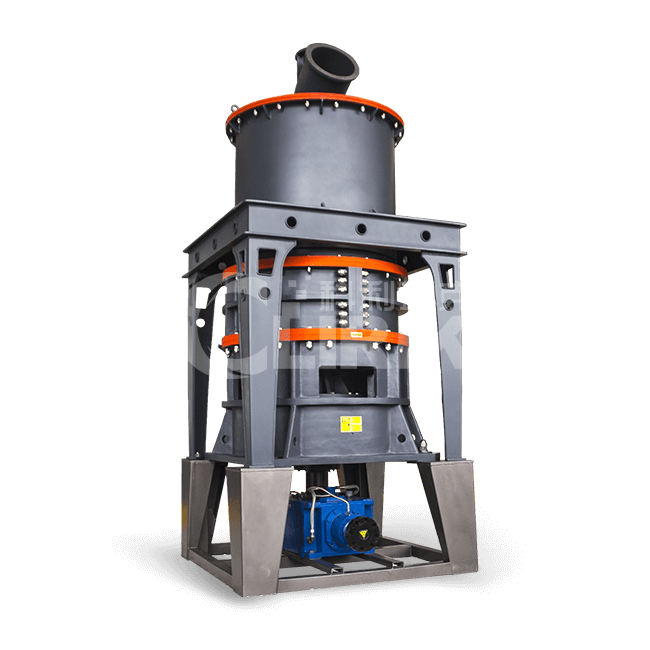

Offer Other Products

Company Profile

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent,standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Pre-sale service:

1. Clirik provides a variety of mining equipment for you to choose from.

2. Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3. Clirik customizes the logo and color of the grinding equipment according to your company image.

4. Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:

1. Clirik provides you with online installation and use videos.

2. Clirik will provide you with technicians to install and debug the grinding equipment.

3. Clirik trains you the technicians who use and maintain the grinding equipment.

4. Clirik provides you with a one-year warranty and lifetime service for the grinding equipment.

Related Products

Messages

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40