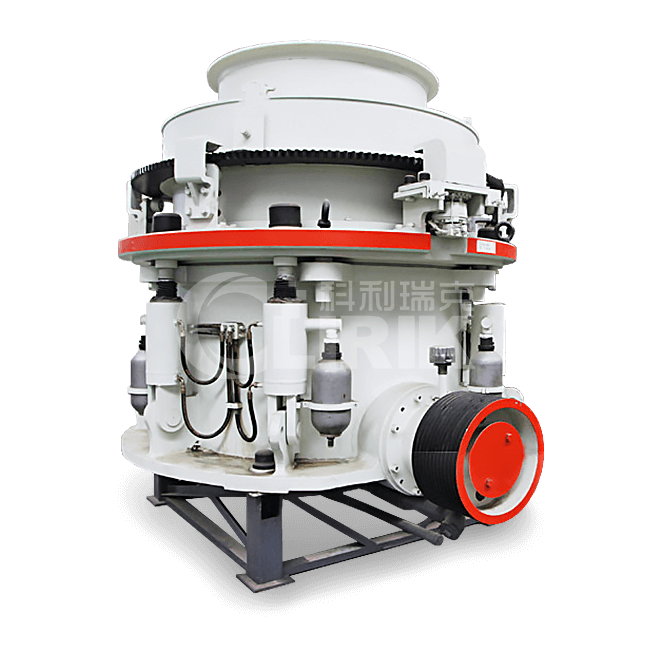

Product Overview

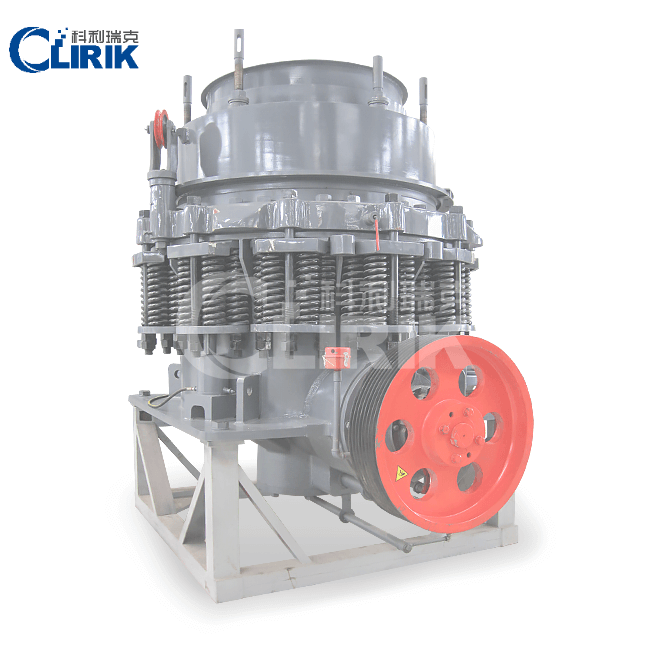

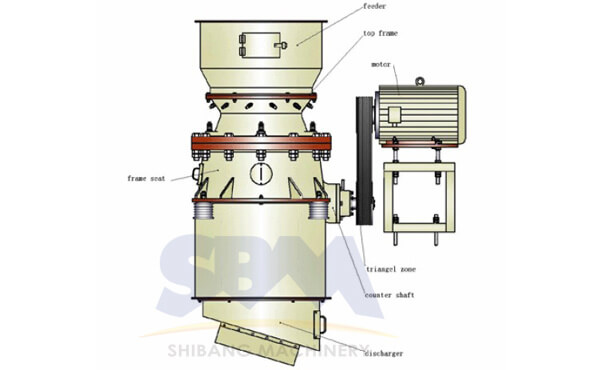

HCS Series Cone Crusher

Processing ability: 27-660t/h

Max feeding size: 275mm

Product Fineness: 10-100mm

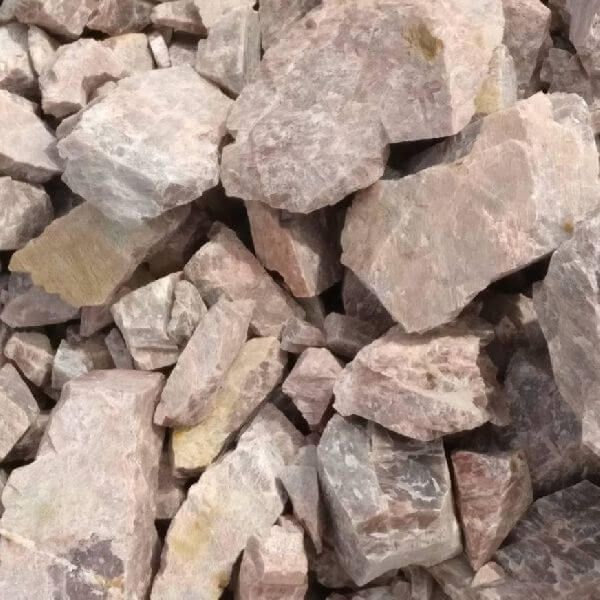

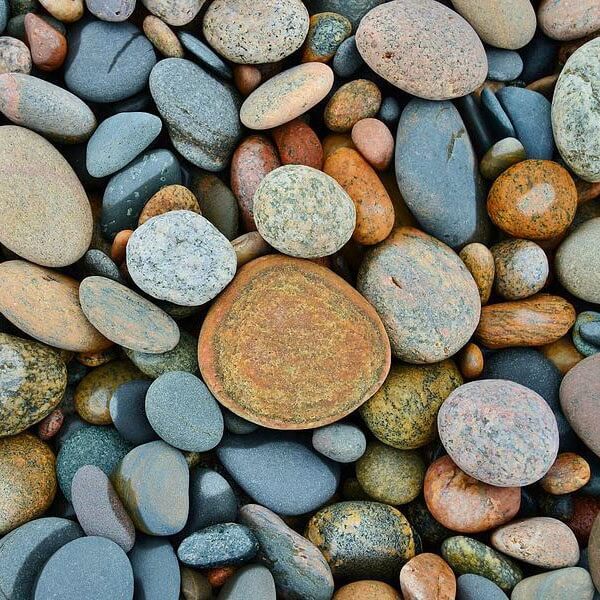

Application: Quartz、Feldspar、Mica, Calcite、 Gypsum、Fluorite、Limestone, Soil、 Clay、 Marble、Granite、Pebble、 Coal、Slag、 Iron Ore、 Copper Ore、 Manganese Ore…

Product Parameter

| Model | Movable Cone Diameter (mm) | Chamber Style | Max Feeding(mm) | Discharge Opening(mm) | Capacity(t/h) | Power(kw) | Machine Size(mm) |

| HCS100 | 790 | EC | 135 | 10-32 | 46-128 | 90 | 1550×1575×1965 |

| C | 90 | 10-25 | 43-118 | ||||

| M | 65 | 8-16 | 36-76 | ||||

| MF | 50 | 6-13 | 29-68 | ||||

| F | 35 | 4-10 | 27-57 | ||||

| EF | 28 | 6 | 30-40 | ||||

| HCS160 | 956 | EC | 180 | 13-38 | 69-215 | 160 | 1875×1920×2400 |

| C | 145 | 13-32 | 65-197 | ||||

| MC | 115 | 10-25 | 60-180 | ||||

| M | 90 | 10-22 | 60-160 | ||||

| MF | 75 | 8-19 | 61-125 | ||||

| F | 50 | 6-19 | 45-105 | ||||

| EF | 35 | 6 | 70-90 | ||||

| HCS250 | 1150 | EC | 215 | 16-44 | 110-380 | 250 | 2100×2320×2780 |

| C | 175 | 13-38 | 100-385 | ||||

| MC | 140 | 13-32 | 95-325 | ||||

| M | 110 | 13-25 | 115-335 | ||||

| MF | 85 | 10-22 | 90-280 | ||||

| F | 70 | 8-19 | 90-235 | ||||

| EF | 38 | 8 | 100-125 | ||||

| HCS315 | 1408 | EC | 275 | 16-44 | 177-660 | 315 | 2380×2735×3265 |

| CX | 245 | 16-38 | 170-650 | ||||

| C | 215 | 16-38 | 170-640 | ||||

| MC | 175 | 16-32 | 160-552 | ||||

| M | 135 | 16-32 | 195-500 | ||||

| MF | 115 | 13-32 | 190-450 | ||||

| F | 85 | 13-25 | 195-400 | ||||

| EF | 65 | 13-22 | 210-300 |

Product Application

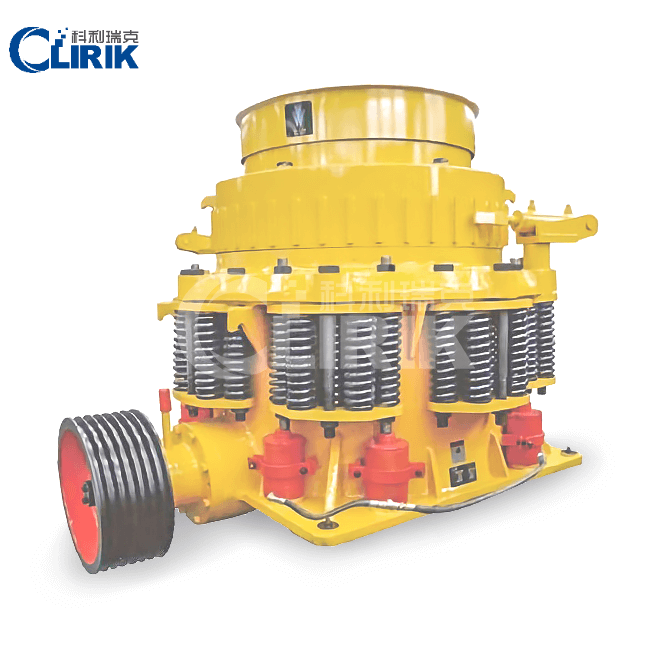

HSC single cylinder hydraulic cone crusher is an optimized design of high performance single cylinder structure hydraulic cone crusher, mainly used in mining, building materials, metallurgy and other industries, can be granite, limestone, river pebbles, basalt, iron ore and other ores, rocks for medium and fine crushing operations.

Applied Materials

Working Principle

When HSC single cylinder hydraulic cone crusher working, motor drives the horizontal drive shaft to rotate through the V-belt, and the horizontal drive shaft drives the eccentric sleeve to rotate through the bevel gear. After the material enters the crushing cavity, it is continuously impacted, squeezed and broken between the crushing wall and the rolling mortar wall. The crushed material is discharged from the lower part.

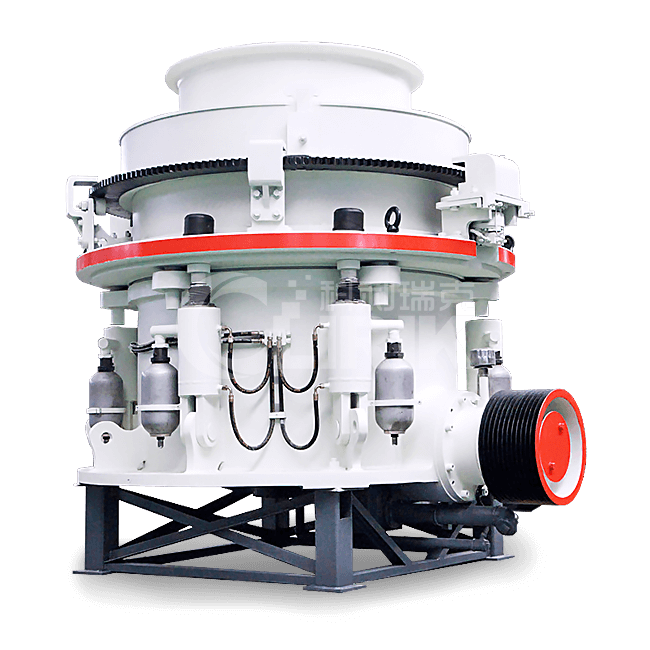

Performance Characteristics

- Reasonable eccentricity and swing frequency and special crushing cavity design make the equipment larger in crushing ratio, higher in output and better in grain shape.

- It integrates the functions of discharge port adjustment and overload protection, with simplified structure and convenient use.

- The intelligent control system can monitor the running status of the equipment in real time, so as to adjust it in time, so that the equipment can always maintain the ideal running state.

- Strengthened equipment structure and advanced overload protection system ensure long-term safe operation of equipment.

Company Profile

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent,standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Our Service

1.Clirik will recommend suitable production lines and grinding equipment to you according to your site.

2.Clirik provides third party inspection to ensure the quality of your grinding equipment.

3. Clirik provides you with online installation and use videos.

4. Clirik will provide you with technicians to install and debug the grinding equipment.

5. Clirik trains you the technicians who use and maintain the grinding equipment.

6. Clirik provides you with a one-year warranty and lifetime service for the grinding equipment.

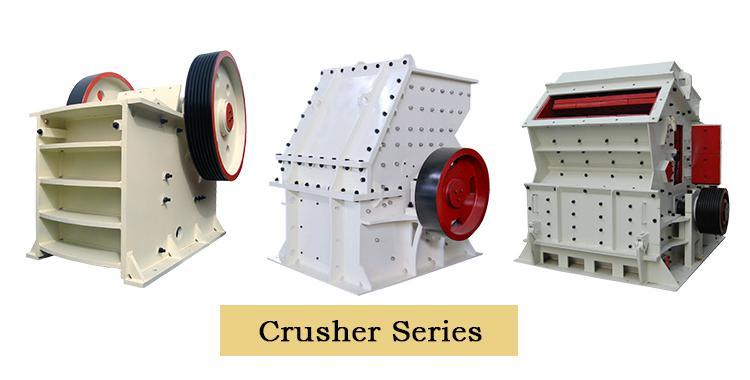

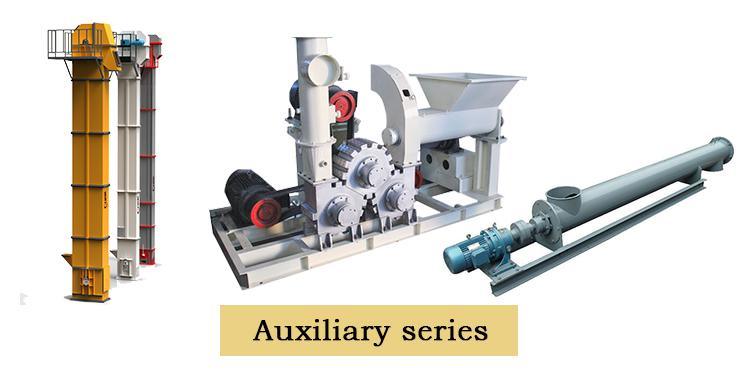

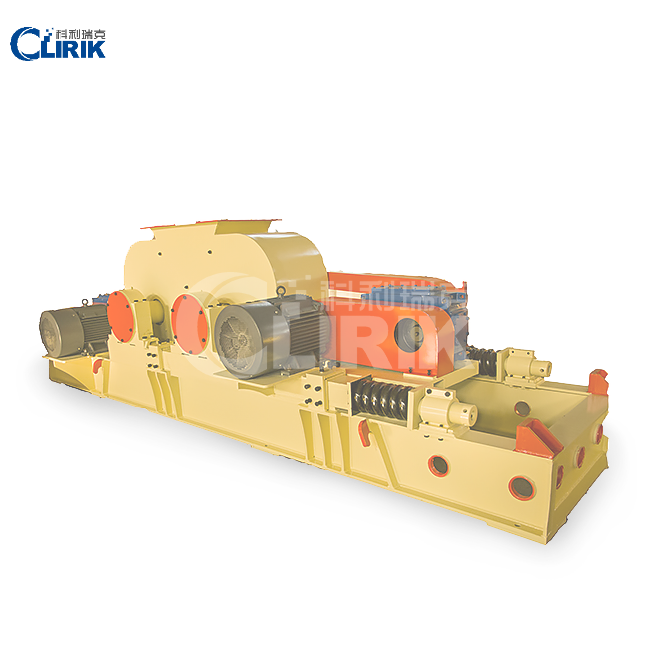

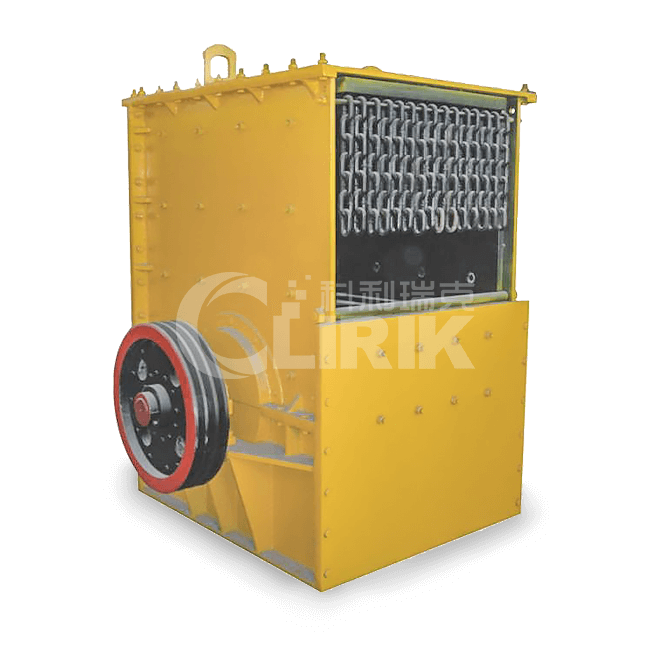

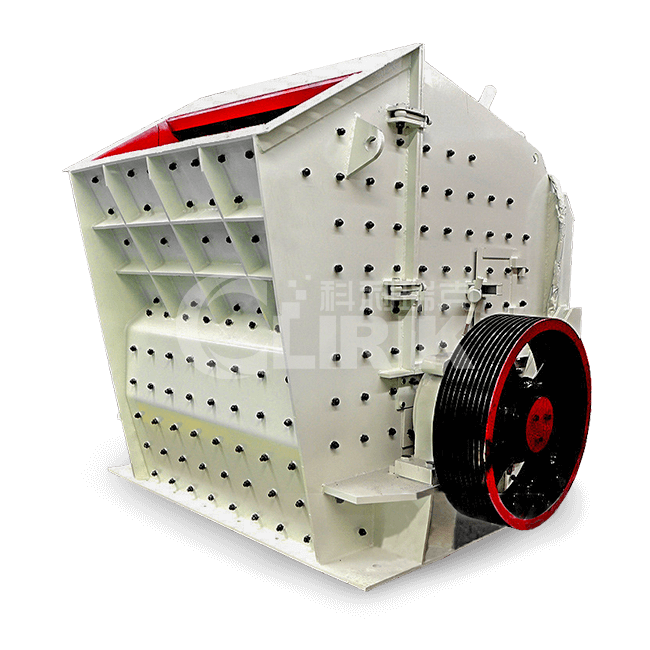

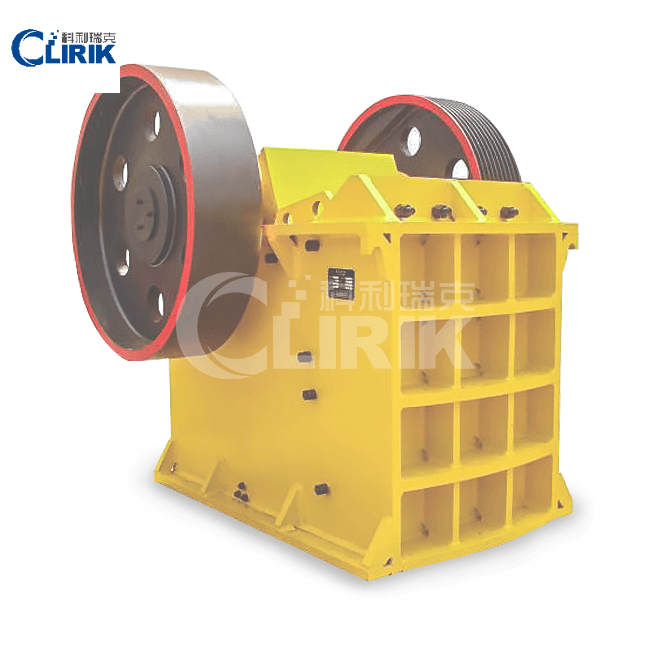

Our Other Equipment

FAQ

Because of different kinds of cone crusher , so our cone crusher has different prices, I need to ask you some details for sending you the more suitable quotation:

1. Which kind of material you are going to grinding?

(Dolomite; Calcite; Quartz; Basalt; Barite; Feldspar ; Gravel; Bentonite; Gypsum; Granite; Coal; Slag; Pebble; Others )

2. What’s the production capacity you want? How many tons or cubic meters per hour?

( > 100 TPH > 50 TPH > 30 TPH > 10 TPH > 1 TPH < 1 TPH)

3. What’s the granularity of the final products you need?

(in milimeter, micron or mesh)

4. What’s the max input size of the material?

(In inch,centimeter or milimeter)

We will give you factory price with full specification,so pls leave us an inquiry to know more details about price, packaging shipping and discount.

Related Products

Messages

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40