Table of Contents

Product Overview

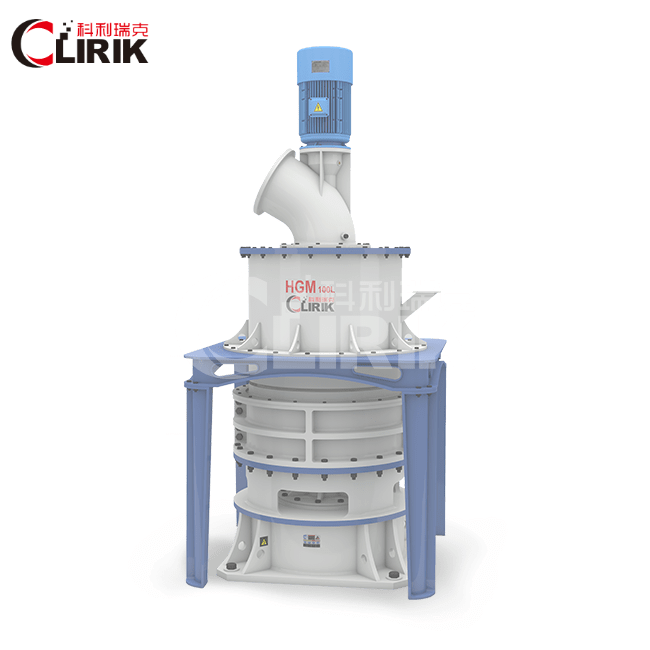

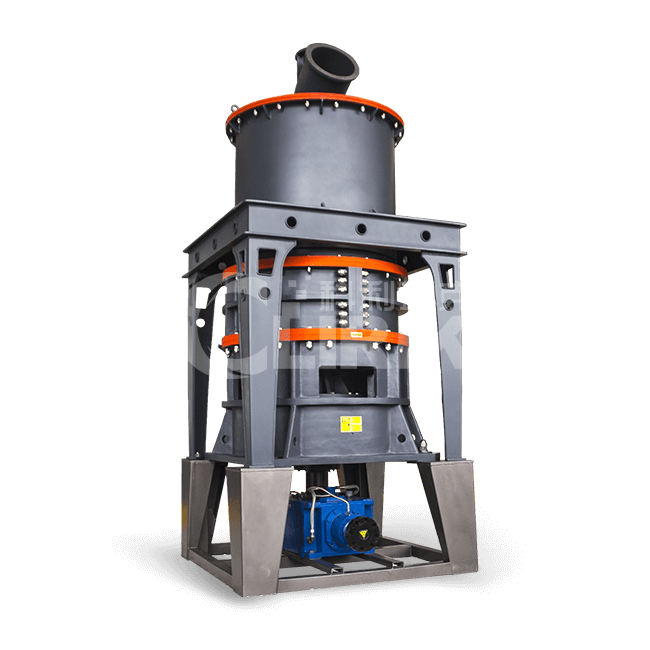

Micro Powder Grinding Mill

Model : HGM series

Brand : Clirik

Fineness Size : 325-3000 mesh

Capacity : 0.5-45 t/h

Use Range : Calcite、Calcium Carbonate、Dolomite、Gypsum、Carbon Black、Gypsum、Kaolin、 Marble …

Application : Mining, Chemiscal, Transport and many other different areas.

Product Parameter

Parameter 1

Parameter of Ultra Fine Grinding Mill| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

Product Advantage

1. High Efficiency

Under the same finished final size and the same motor power, HGM series micro powder grinding mill is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

2. Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization, the lifetime can reach 2-5 years for grinding calcite carbonate.

3. High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

4. High fineness, flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 2500 mesh (47-5 micron), and the product fineness can reach D97≤ 5μ M.

5. Environment-friendly

The application of pulse bag filter and muffler greatly alleviates dust pollution and noise.

Advanced intelligent speed control device

Convenient adjusting, more uniform particle size.

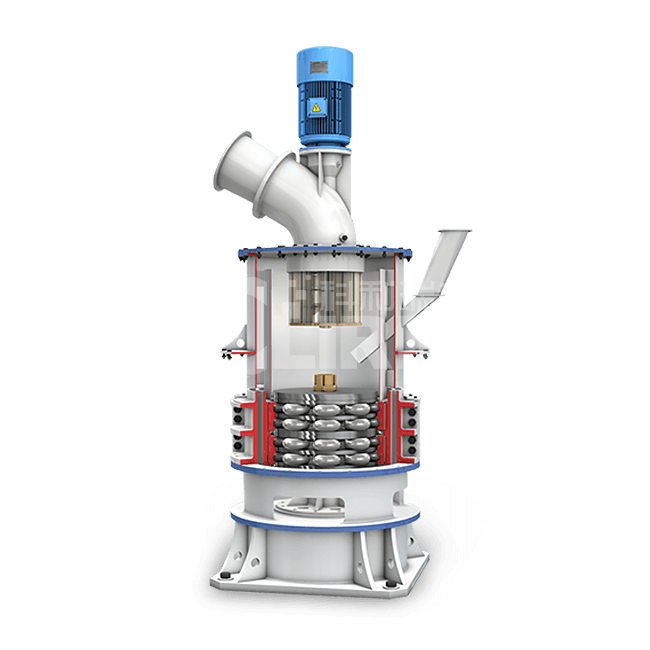

Working Principle

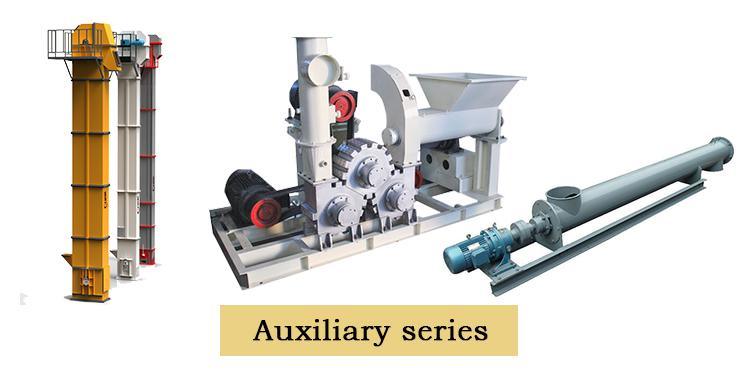

HGM series micro powder grinding mill mainly consist of main unit, classifire,powder collector,dust cleaner ,blower, muffler,sound-proof room,crusher,bucket elevator,storage hopper,and vibrating feeder.

1. After crushed by hammer crusher,the large materials become small ones and are sent to storage hopper by elevator .

2. Then evenly sent to the upper distribution plate of the turn plate by vibrating feeder and sloping feeding pipe.

3. When the grinding mill is at work,the main bearing and each dial are driven by electromotor of main equipment through reducer,and all the grinding rollers are rolling in the ring channels driving by dial through plunger.

4. The materials are driven to the edge of the turn plate by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed, crushed and grinded by the rollers. then the materials fall into multiple layers and to be crushed and ground continuously to micro powder.

5. The high-pressure air blower constantly inhales air within the grinding mill and, in turn,the airflow with crushed materials are brought to the classifier whose high-speed impeller will screen the airflow:the unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with ari will go into the cyclone powder collector.

6. Most of the qulified powders will fall and exit from the discharging valve at the bottom;a small proprotion of the fine powders,with airflow,moves to by the sudden vibration of the filter bags,which is caused by the instantly ejected high-pressure gas controlled by the pulse valve.

7. The materials from the above two lost are sent by the conveyor at the bottom to get finished powders packed. In addition,filtered clean air will be emitted from the air outlet of muffler in the end.

Services Enjoyed

Pre-sale Service:

1. Offers a variety of mining equipment for you to choose from.

2. Recommend suitable production lines and grinding equipment for you according to your site.

3. According your company image, customize the logo and color of the grinding equipment

4. Provides third party inspection to ensure the quality of your grinding equipment.

After-sale service:

1. Provides you with online installation and usage videos.

2. Provide you with technicians to install and debug the grinding equipment.

3. Trains your technicians in the use and maintenance of grinding equipment.

4. Provides you with a one-year warranty for grinding equipment, as well as the accessories you need in the later period, and lifetime service.

Related Products

Messages

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40