Table of Contents

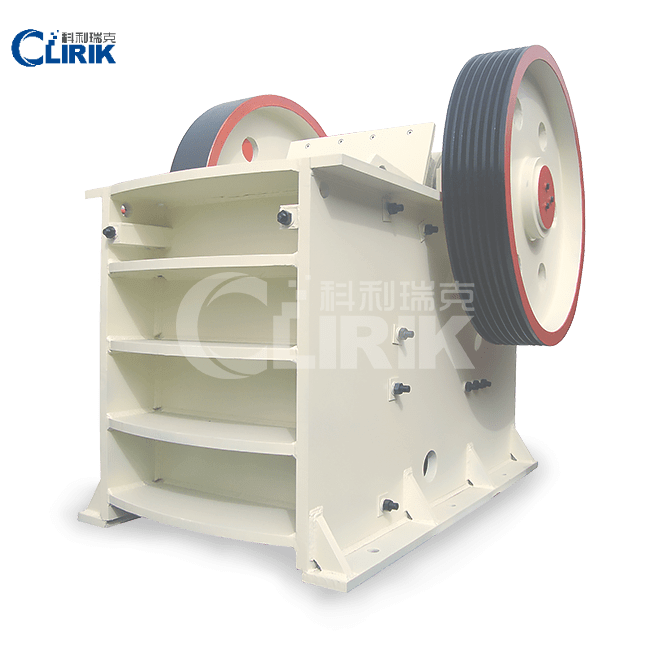

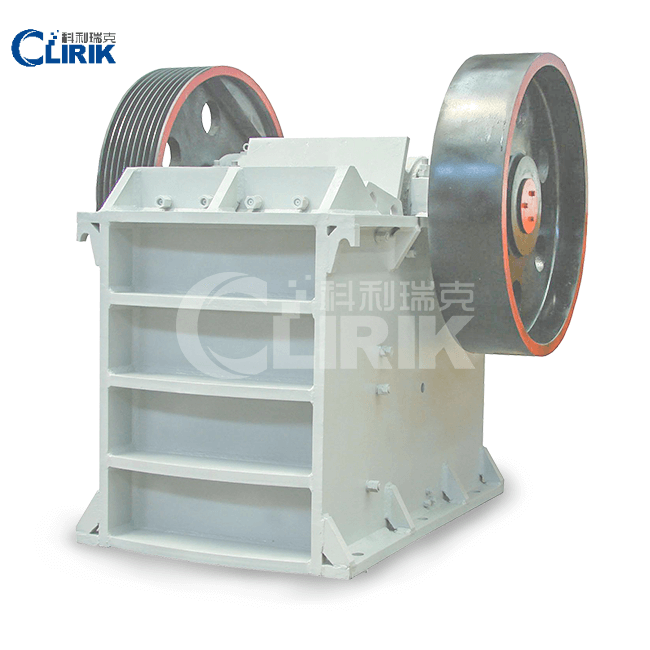

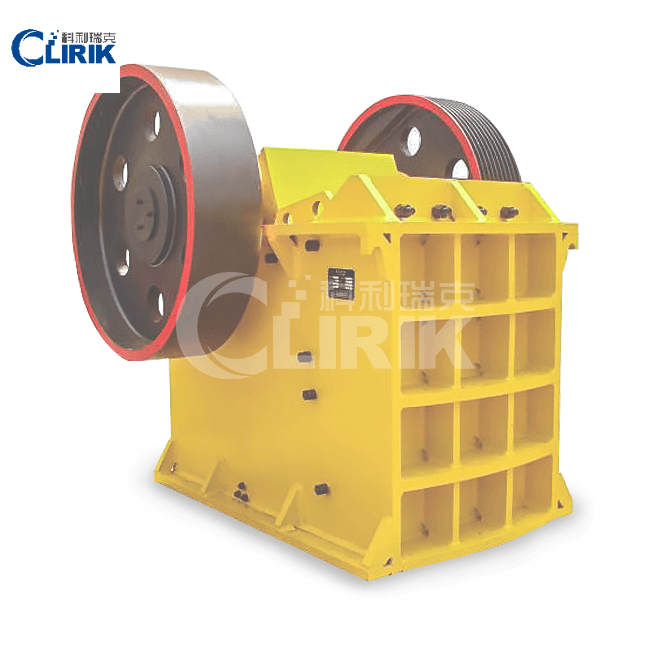

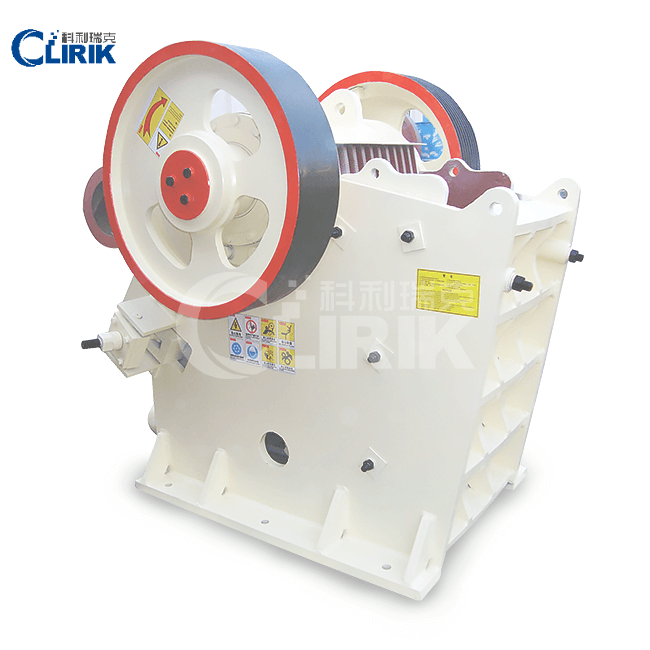

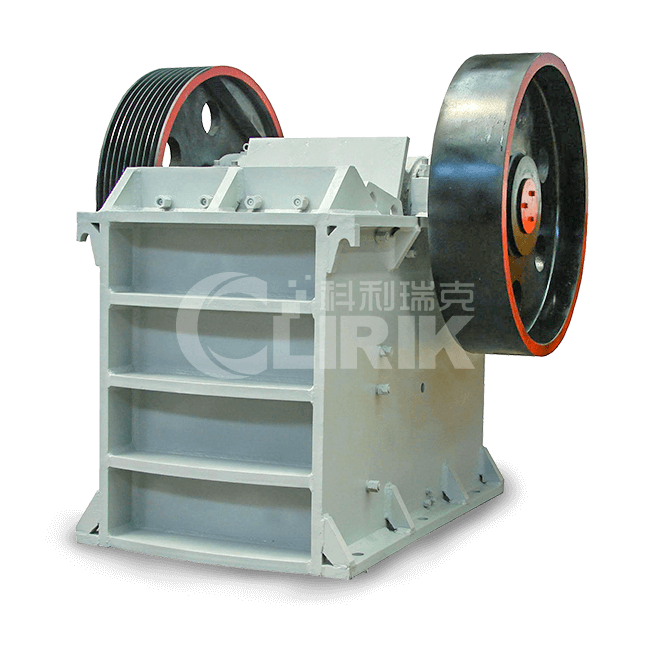

Jaw Crusher

Output Size: 25-105 mm

Feed size.: <250 mm

Capacity: 1-90 t/h

Use Range : Calcite、Calcium Carbonate、Dolomite、Gypsum、Carbon Black、Gypsum、Kaolin、 Marble …

Application : Mining、Chemiscal、 Pigment、 Plastic、Transport and many other different areas.

Product Parameter

| Model | PEX-150 × 250 | PEX-150 × 750 | PEX-250 × 750 | PEX-250 × 1000 | PEX-250 × 1200 | PEX-300 × 1300 |

| Opening Size(mm) | 250 × 150 | 750 × 150 | 750 × 250 | 1000 × 250 | 1200 × 250 | 1300 × 300 |

| Feed Size(mm) | 125 | 125 | 210 | 210 | 210 | 250 |

| Output Open Range(mm) | 10-40 | 18-18 | 25-60 | 25-60 | 25-60 | 25-105 |

| Power(KW) | 5.5 | 15 | 22-30 | 30-37 | 37 | 75 |

| Capacity(t/h) | 1-5 | 5-16 | 15-30 | 16-50 | 20-60 | 20-90 |

| Size(mm) | 875 × 758 × 850 | 1200 × 1500 × 1200 | 1667 × 1545 × 1020 | 1530 × 1992 × 1380 | 1900 × 2192 × 1430 | 2720 × 1950 × 1600 |

| Weight(t) | 0.81 | 3.8 | 5/td> | 7 | 8 | 11 |

Product Application

The PEX Series Jaw Crusher consists of two jaw plates, a movable jaw, and a static jaw, forming a crushing chamber, which simulates the movement of the two jaws of an animal to complete the material crushing operation. It is widely used in stone mining, metallurgy industry, building material, highway, railway, water conservancy, and chemical industries. Various materials with compression resistance less than 320MPa can be crushed.

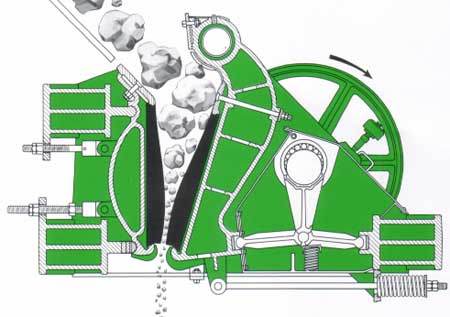

Working Principle

The working mode of PEX jaw crusher is mobile and extrusion. The working principle is as follows: The jaw crusher uses the motor as the powder. The eccentric shaft is driven by the wheels of the motor, the V-belt, and the grooved wheel so that the movable jaw plate moves according to the prescribed orbit.

Therefore, the material in the crushing cavity which is composed of the fixed jaw plate, movable jaw plate, and the side backplate, can be crushed and discharged through the discharge port.

When the jaw crusher is working, the movable jaw plate cyclically reciprocates against the fixed jaw plate, sometimes approaching and sometimes leaving.

When approaching, the material is crushed by squeezing, splitting, and impact between the two jaws; when leaving, the crushed material is discharged from the discharge port by gravity.

Product Advantage

1 High crushing ratio, uniform particle size.

2 Point eclipse discharge opening adjustment devices, reliable and easy to adjust the range to meet the needs of different customers.

3 Safe and reliable lubrication system, easy to replace parts, low maintenance workload.

4 Simple structure, reliable function, low operating cost.

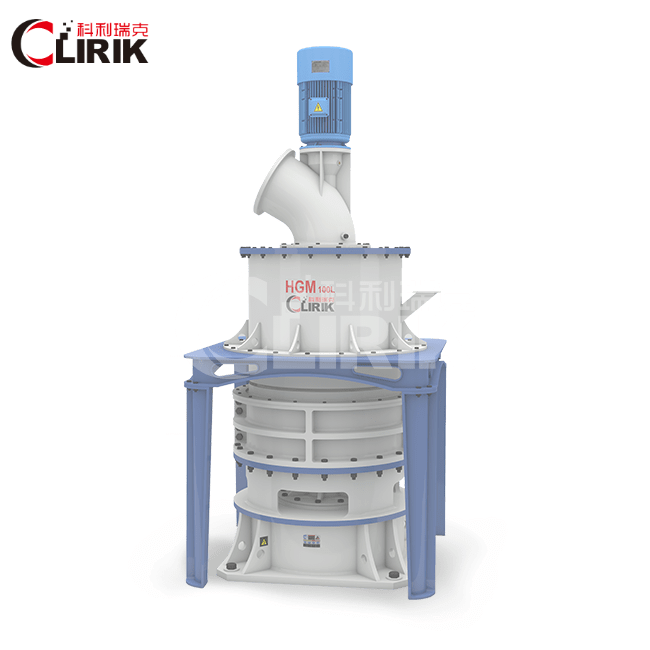

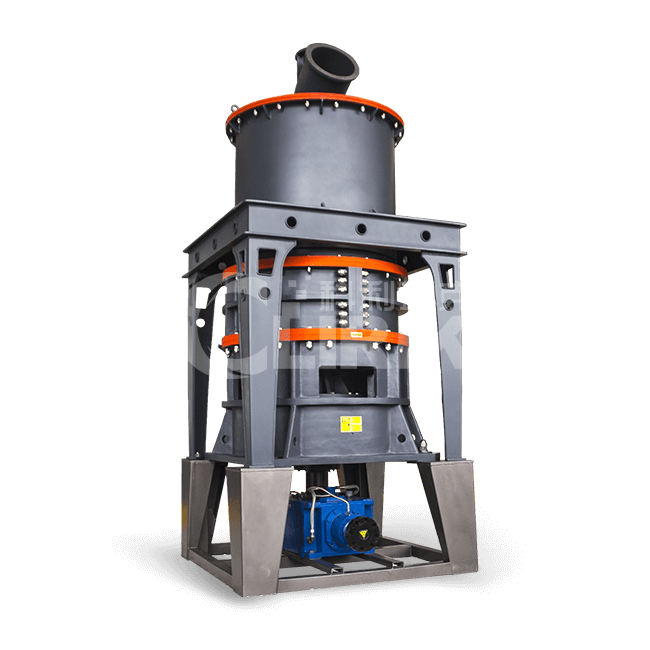

Other Products Offered

Company Profile

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent,standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Pre-sale service:

1.Clirik provides a variety of mining equipment for you to choose from.

2.Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3.Clirik customizes the logo and color of the grinding equipment according to your company image.

4.Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:

1. Clirik provides you with online installation and use videos.

2. Clirik will provide you with technicians to install and debug the grinding equipment.

3. Clirik trains you the technicians who use and maintain the grinding equipment.

4. Clirik provides you with a one-year warranty and lifetime service for the grinding equipment.

Related Products

Messages

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40