Table of Contents

Product Overview Of TD Belt Elevator

TD belt elevator is the related equipment of Grinder Mills, also known as a kind of bucket-type elevator. TD series belt elevator is suitable to lift powder, granular, and bulk materials with small grinding suction, such as grain, coal, cement, crushed ore, up to 40m. The common models of TD series belt elevator are TD100, TD160, TD250, TD315, TD400, TD500, TD630, TD800, TD1000, etc. Among them, TD160, TD250, TD315 are the most common types. Shanghai Clirik TD series belt elevator is available in four kinds of hopper: Q -type (light bucket), H type (arc-bottom bucket), the ZD type (deep bucket) the SD type (deep bucket).

TD belt elevator according to its hopper’s speed, can be divided into: centrifugal discharge, gravity discharge and hybrid discharge. Centrifugal discharge, with high-speed hopper, is suitable for conveying powder, granular, small block, and abrasive materials. Gravity discharge, with slow-speed hopper, is suitable for conveying the block, materials with a large size and abrasive, such as limestone, clinker. Traction component of the bucket elevator includes chain, plate chain and tape. The structure and manufacturing of the chain is relatively simple but heavy, also in strong connection with the hopper, suitable for conveying of abrasive materials. Plate chain, with strong and light structure, is suitable for lifting heavy hoist, but hinged joints susceptible to wear. The structure of the tape is relatively simple, but not suitable for conveying abrasive materials .The temperature of material to be conveyed should be lower than 60 ° C for ordinary tape, 80 ° C for steel-rope tape, 120 ° C for heat-resistant tape, and 250 ° C for chain , plate chain.

Product Parameter Of TD Belt Elevator

TD belt elevators are available in a variety of models.

| Model | TD160 | TD250 | ||||||

| Bucket Shape | Q | H | Zd | Sd | Q | h | Zd | Sd |

| carrying capacity (m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 |

| Bucket Width(mm) | 160 | 250 | ||||||

| Bucket volume (L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 |

| Pitch of Bucket (mm) | 280 | 350 | 360 | 450 | ||||

| Tape Width(mm) | 200 | 300 | ||||||

| Bucket Speed(m/s) | 1.4 | 1.6 | ||||||

| Material Size(mm) | 25 | 35 | ||||||

| Model | TD315 | TD400 | ||||||

| Bucket Shape | Q | H | Zd | Sd | Q | H | Zd | Sd |

| carrying capacity (m3/h) | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket Width(mm) | 315 | 400 | ||||||

| Bucket volume (L) | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Pitch of Bucket (mm) | 400 | 500 | 480 | 560 | ||||

| Tape Width(mm) | 400 | 500 | ||||||

| Bucket Speed(m/s) | 1.6 | 1.8 | ||||||

| Material Size(mm) | 45 | 55 | ||||||

| Model | TD500 | TD630 | ||||||

| Bucket Shape | Q | H | Zd | Sd | Q | H | Zd | Sd |

| carrying capacity (m3/h) | 38 | 70 | 58 | 92 | X | 85 | 89 | 142 |

| Bucket Width(mm) | 500 | 630 | ||||||

| Bucket volume (L) | 4.8 | 9 | 9.3 | 15 | X | 14 | 14.6 | 23.5 |

| Pitch of Bucket (mm) | 500 | 625 | 710 | 710 | ||||

| Tape Width(mm) | 600 | 7 | ||||||

| Bucket Speed(m/s) | 1.8 | 1.8 | ||||||

| Material Size(mm) | 60 | 55 | ||||||

| Model | D160 | D250 | D350 | D450 | ||||

| Bucket Shape | Q | S | Q | S | Q | S | Q | S |

| carrying capacity (m3/h) | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 |

| Bucket Width(mm) | 160 | 250 | 350 | 450 | ||||

| Bucket volume (L) | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 |

| Pitch of Bucket (mm) | 300 | 400 | 500 | 640 | ||||

| Tape Width(mm) | 200 | 300 | 400 | 500 | ||||

| Bucket Speed(m/s) | 1 | 1.25 | 1.25 | 1.25 | ||||

| Material Size(mm) | 25 | 35 | 45 | 55 | ||||

Note: Bucket Capacity above is calculated capacity and Carrying Capacity is calculated at the filling coefficient of 0.6.

Product Benefit Of TD Belt Elevator

1. With observation hole and the tensioning device, high output, stable performance.

2. With small Drive power, inflow-type feed, induction-type discharge, Large-capacity hopper, intensive layout; almost no recalculating scrap.

3. Base with arc –shaped bottom, minimal residual materials, more convenient cleaning.

4. Barrel with special combination folding process, high strength, good sealing.

5. Power adjustable according to the lifting height.

Product Maintenance Of TD Belt Elevator

1. Operating procedures.

(1) The operator should be familiar with the performance characteristics and instructions of the TD belt elevator, and master the operation process and safety regulations of the device.

(2) Before starting the TD belt elevator, the operator should check whether the fasteners of the equipment are tight, if found loose should be tightened in time.

(3) Check whether there is oil in the reducer of the TD belt elevator. If there is no oil, add oil and check whether there is oil in each lubrication point.

(4) Check whether the belt is missing hopper or hopper is loose. If it is found, deal with it in time.

(5) Check whether the traction belt runs off course, stretches and tears. If there is any problem, stop the machine on time.

(6) Check whether there is material blockage at the bottom of the machine. If there is, it should be cleaned in time to avoid overload operation of the equipment and damage to other parts.

(7) Check the transmission device, whether the transmission belt is elongated, if found, should be adjusted or replaced.

2. Maintenance.

(1) TD belt elevator lift machine drive reducer work for three months, need to change the oil once.

(2) Each lubrication point should be lubricated with grease every month.

(3) It is found that the conveyor belt of the belt bucket lift machine is broken, which should be treated or replaced in time.

(4) Check whether the anti-skid device of the TD belt elevator is worn regularly. If damaged, it should be dealt with in time.

Introduce The Manufacturer Of TD belt elevator

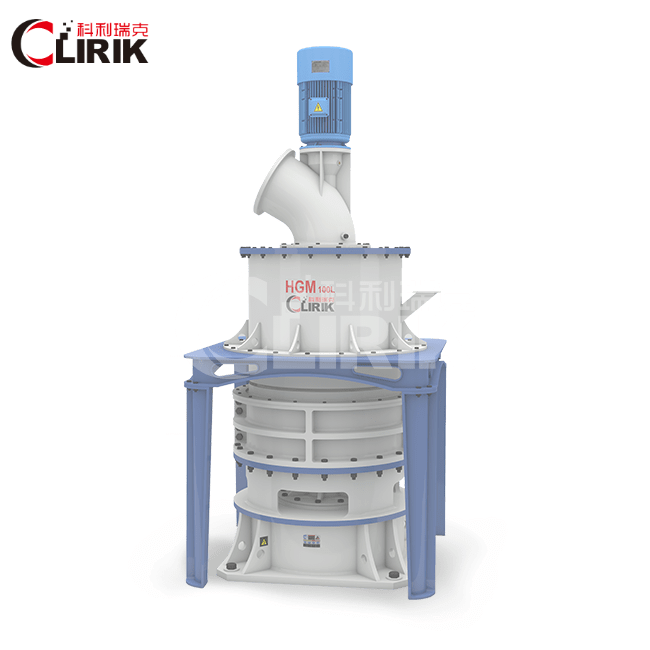

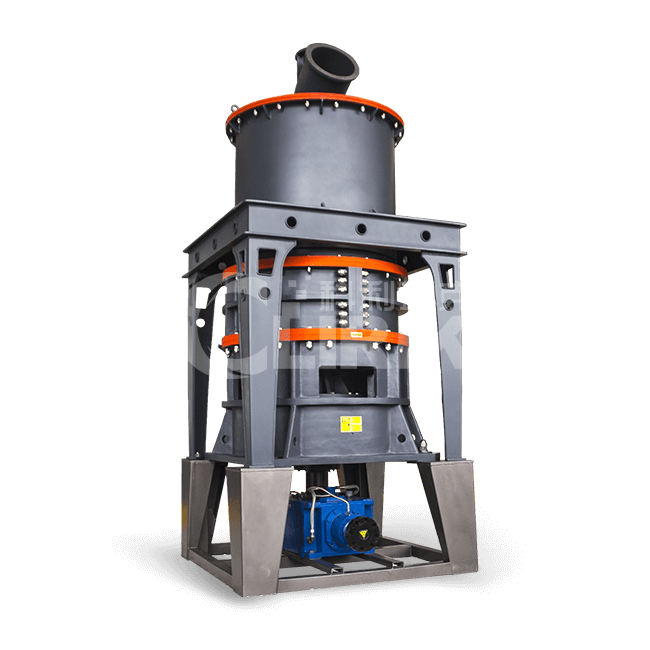

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai China as a professional enterprise, which specializes in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production lines, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

So far, we have established a whole production chain, the products cover micro powder grinding mill, high pressure grinding mill, Europe a version coarse powder grinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on.

FAQ

1. Do you have an after-sales service?

All of our products have after-sales quality assurance services.

2. How long is your delivery time?

Generally, it is 10-15 days if the goods are in stock.

or it is 15-20 days if the goods are not in stock, it is according to quantity.

3. How to carry out transportation?

Express, sea transport, land transport, air transport, self – lift can be based on your needs.

4. What are the terms of payment?

L/C, Western Union, D/P, D/A, T/T, MoneyGram, Alibaba.com Pay, cash.

5. Are you a trading company or manufacturer?

We are a factory.

6. If I need an ores stone powder production line, can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We have already built many mining projects in China & overseas.

Related Products

Messages

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40