The primary use of barite powder is as a weighting agent in drilling fluids used in oil and gas exploration and production.

The calcium carbonate industry is transforming —— Clirik CLUM series ultrafine vertical mill

The calcium carbonate industry is transforming —— Clirik CLUM series ultrafine vertical mill

Table of Contents

From high output to high quality– Ecological transformation of calcium carbonate industry

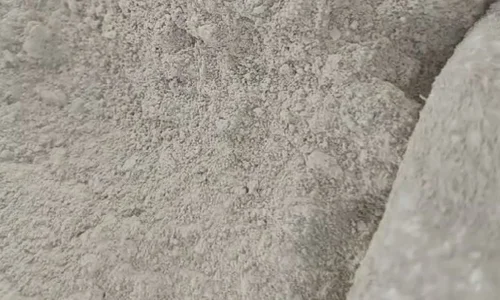

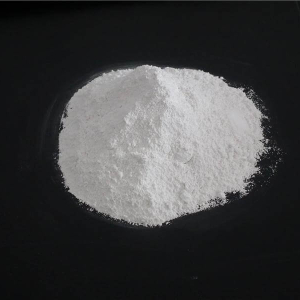

Calcium carbonate is mainly ground from natural carbonate minerals such as calcite. Because of its obvious reinforcement, whitening effect, easy processing and low cost, it is often used as a filler in production. It is used in papermaking, plastics, rubber, coatings, sealants and other industries. In recent years, with the rapid development of these industries, the demand for ground calcium carbonate is also further increasing.

Since 2021, calcium carbonate has accounted for more than 60% of the overall calcium carbonate industry, and it has shown a year-by-year growth trend. Affected by the continuous growth of overall demand, the price of calcium carbonate continued to increase. However, the overall market for calcium carbonate is relatively saturated at present, and the overall profit and added value are slightly lower. The transformation of creating high added value and industrial ecology will become the main driving force for industrial development.

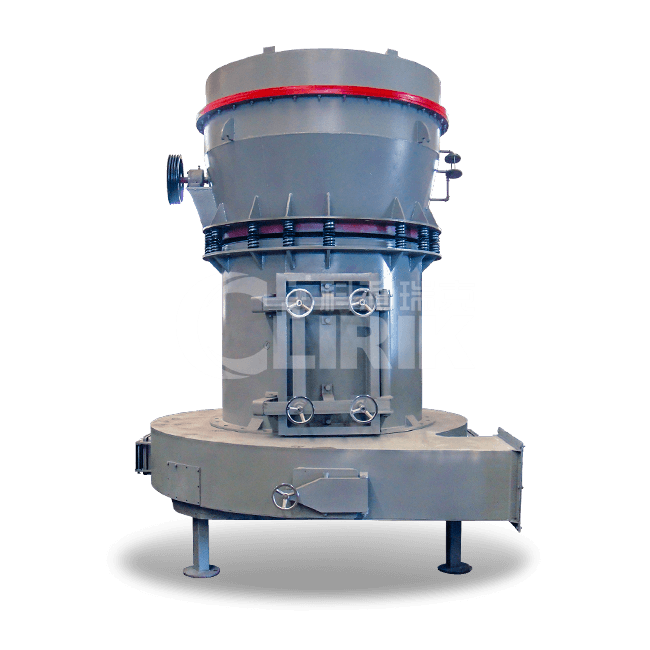

Among them, the mill is the core of the calcium carbonate production line. For a long time, traditional grinding machines use centrifugal force for grinding, the reason why the rollers and grinding discs are often in direct contact, the noise, equipment loss, power consumption, and large pollution during the preparation process have seriously affected the work efficiency.

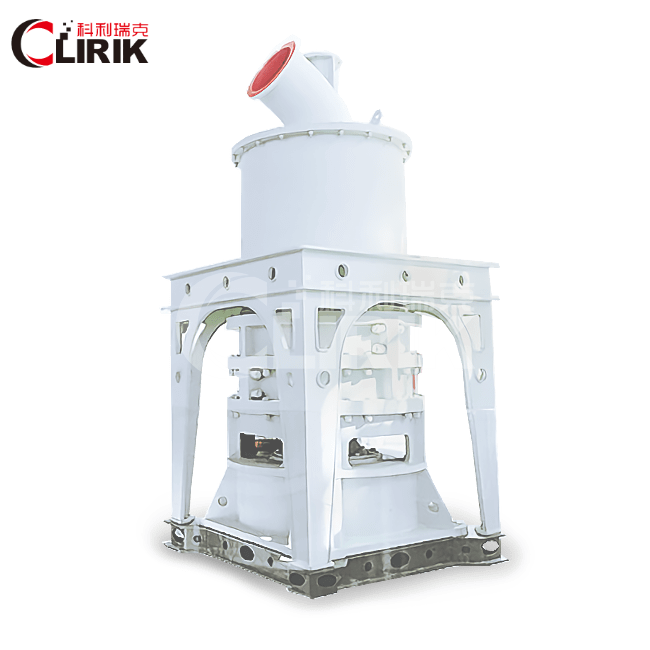

As a domestic enterprise specializing in the research of industrial powder equipment, Shanghai Clirik Machinery Co., Ltd. has combined years of experience in the production of mills, introduced ultra-fine vertical mill technology from Taiwan and Germany, and designed and developed a set of grinding, grading, A new type of ultra-fine grinding equipment integrating conveying, secondary powder selection, and finished product packaging: CLUM series ultrafine vertical mill to meet the market demand for high production capacity and environmental protection.

CLUM series ultrafine vertical mill features

1. Because the grinding roll and the grinding disc are not in direct contact during work, there is no metal impact sound in the work of the ball mill, and the vibration of the equipment is small during operation.

2. The equipment is sealed as a whole, the system works under negative pressure, and the finished products are directly sent to the large finished product warehouse by the gas conveying equipment. There is no dust spillover, and the production environment is clean.

New key words of calcium carbonate industry —— Intensive, intelligent, automatic

In recent years, from the perspective of the healthy development of the calcium carbonate manufacturing industry, a series of industrial policies have been introduced. macro-control of non-metallic mineral products has continued to increase, and outdated production processes with high energy consumption, high pollution, and low utilization rate have been eliminated. , Through industrial policies, guide the industry to concentrate on “high” new enterprises with high level of science and technology, high degree of automation, high resource utilization rate, and high degree of standardization, and guide the product structure to tilt towards high value-added deep-processing products.

As an emerging enterprise specializing in the research, manufacture and sales of industrial powder equipment, Shanghai Claric Machinery Co., Ltd. has an independent production and manufacturing base, an automated and intelligent production line and a control laboratory. The company’s CLUM series ultrafine vertical mill can meet the ultra-fine powder application needs of different customers, and match demand and quality requirements for high-quality calcium carbonate powder.

CLUM series ultrafine vertical mill advantages

Intelligent frequency conversion speed regulation

The material is put into the grinding evenly, the particle size of the finished product is more stable, and the particle size cutting precision is high.

High-precision multi-head powder separator

Using frequency conversion control, the rotor speed can be adjusted arbitrarily, and products with multiple specifications can be obtained.

adjustable hydraulic system

The pressure is adjusted in multiple stages, and it can adapt to materials with different hardness within a certain range.

Multi-electronic limit device

Ensure the safety gap between the grinding roller and the grinding plate, effectively avoid the vibration caused by material breaking.

Innovation technology to ensure the vitality of products —— Clirik with “new” manufacturing

Over the years, Shanghai Clirik Machinery Co., Ltd. has always adhered to the three “high” spirits of high efficiency, high technology and high cost performance to serve global customers. Our company has long insisted on maintaining communication and cooperation with several scientific research institutions at home and abroad to ensure the scientific research vitality of the equipment, and the equipment and products are exported to all over the world.

The sun and the moon flow like a stream, and they live endlessly. Over the years, we have served customers, realized value, and made many memories together. In the process of mutual achievement, Shanghai Clirik Machinery Co., Ltd. also relies on its own strong scientific and technological strength and grinding technology to continuously improve and precipitate.

CLUM series ultrafine vertical mill Characteristic

The operating cost of CLUM series ultrafine vertical mill has dropped sharply under the blessing of new technology

Grinding wheel and disc liner are made of special alloy wear-resistant material. The material forms a stable and effective material bed, the vibration of the whole machine is small, the powder forming rate is 20% higher than that of similar domestic products, and the energy consumption of equipment such as ball mills is reduced by 40%.

Intelligent grading equipment ensures high added value of products

The high-efficiency precision rotor adopts PLC frequency conversion control system. After the ultra-fine powder produced by CLUM series ultra-fine vertical mill is classified, it can realize the production of products with a content of 2 microns exceeding 60%.

Efficient, safe and stable operating system

The main engine equipped with multiple intelligent protection devices can realize continuous operation without stopping.

A new model of green industrial production: green, quiet, and environmentally friendly

Since the grinding roller and the grinding disc are not in direct contact during work, there is no metal impact sound when the ball mill is working, the equipment is sealed as a whole, the system works under negative pressure, no dust spills, and the production environment is clean.

Intelligent central control system: take the lead in realizing intensification and visualization

The central control system of CLUM series ultrafine vertical mill has realized the automation, intelligence and centralization of the production line, and the remote visual operation can meet various control requirements of customers. The damage to the mill caused by human factors is avoided, and the operation rate of the mill is improved.

More product recommendations

The products of Clirik Machinery Co., Ltd. cover: CLUM series ultra-fine vertical mill, HGM series ultra-fine mill, YGM series high-pressure suspension roller mill, CLG series powder modification machine, CM series powder modification machine machine, and powder supporting products.

Scan the QR code to read on your phone

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40