The primary use of barite powder is as a weighting agent in drilling fluids used in oil and gas exploration and production.

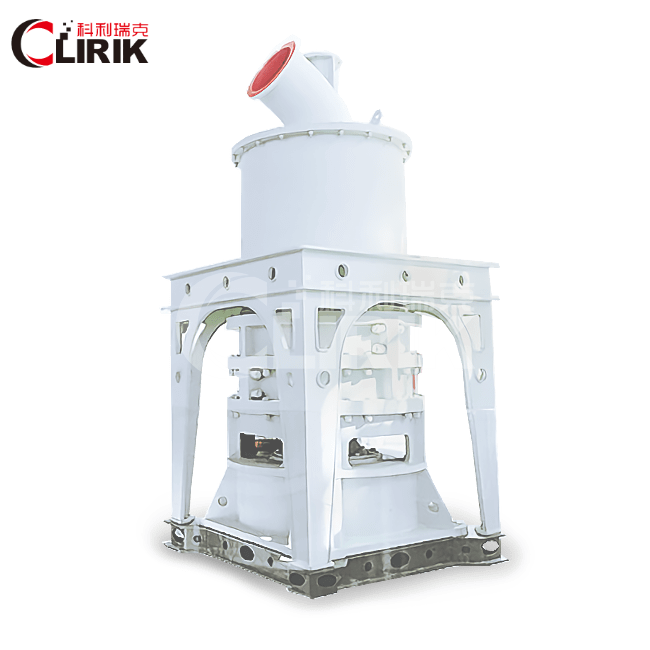

What are the advantages of Barite ultrafine powder grinding mill?

What are the advantages of Barite ultrafine powder grinding mill?

Barite ultrafine powder grinding mill advantages

High efficiency

The barite ultrafine powder grinding mill is designed to grind the material with high efficiency and precision. It has a high grinding ratio, which means it can produce more powder with less energy.

Wide range of application

Barite ultrafine powder grinding mill can grind various materials with a hardness below 9.3 and a humidity below 6%, such as barite, calcite, marble, limestone, talc, dolomite, and so on.

Adjustable fineness

The ultrafine powder grinding mill can adjust the fineness of the finished product according to the needs of customers. The fineness can be adjusted from 325 mesh to 2500 mesh.

Energy saving

Barite ultrafine powder grinding mill adopts advanced grinding technology, which can save energy consumption by 30% to 50% compared with traditional grinding mills.

Environmental protection

The ultrafine powder grinding mill adopts pulse dust collector and muffler to reduce dust and noise pollution, which is environmentally friendly.

Easy maintenance

The ultrafine powder grinding mill is equipped with a hydraulic system, which can quickly replace the grinding roller and grinding ring without dismantling the whole machine, reducing maintenance time and improving efficiency.

In summary, Barite ultrafine powder grinding mill has advantages in high efficiency, wide range of application, adjustable fineness, energy saving, environmental protection, and easy maintenance, making it an ideal choice for grinding barite powder.

Barite ultrafine powder grinding mill working principle

Barite ultrafine powder grinding mill is the working principle as follows:

Firstly, the material is crushed by the jaw crusher or hammer crusher and then transported to the storage bin by the elevator. Then, the material is evenly and continuously sent to the grinding chamber of the mill by the vibrating feeder for grinding. The ground powder is blown by the blower to the classifier for classification.

The classifier separates the powder into different particle sizes according to the specific gravity of the particles. The coarse particles are returned to the grinding chamber for re-grinding, while the fine powder is collected by the dust collector and then discharged through the discharge valve.

During the grinding process, the grinding roller and grinding ring are in contact with the material, and the grinding roller rotates around its own axis, while the grinding ring rotates around the grinding roller. The material is ground by the friction and impact between the grinding roller and grinding ring.

The working principle of the barite ultrafine powder grinding mill is crushing, grinding, and classification. It uses the principle of mechanical grinding to grind the material into ultrafine powder, and then separates the powder according to its particle size using the classifier.

If you would like to know more about this, please click here and leave us a message with your specific requirements, and our sales manager will contact you later.

Scan the QR code to read on your phone

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40