The primary use of barite powder is as a weighting agent in drilling fluids used in oil and gas exploration and production.

What is barite ultrafine powder grinding mill?

What is barite ultrafine powder grinding mill?

Barite ultrafine powder grinding mill brief

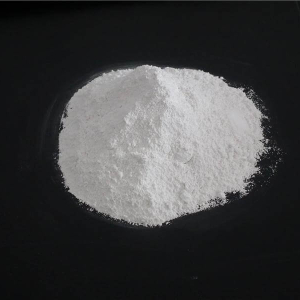

Barite is a mineral that is commonly used in various industries such as oil and gas, chemicals, and paint industries. Barite is also used as a weighting agent in drilling muds for oil and gas exploration.

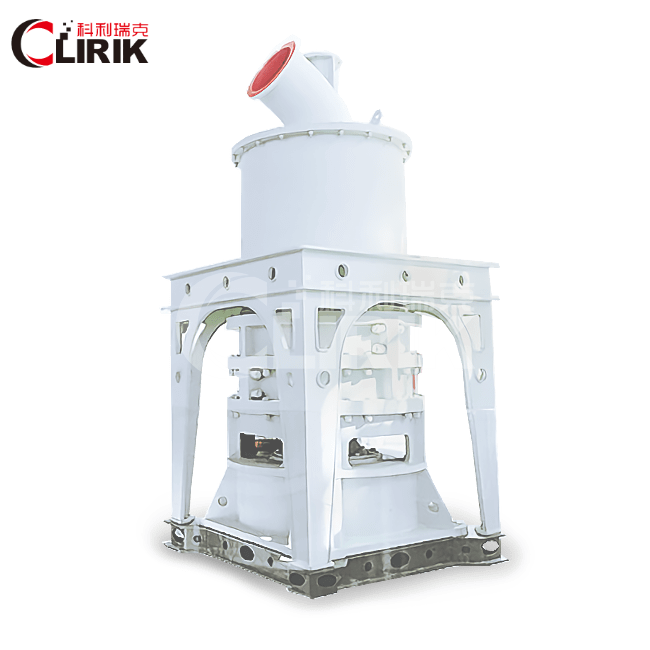

Barite ultrafine powder grinding mill is a specialized equipment for grinding and processing barite into fine powder, which is also called barite ultrafine powder grinder or barite ultrafine mill. This type of mill is capable of producing a wide range of particle sizes, from relatively coarse to very fine, with high efficiency and low energy consumption.

The barite ultrafine powder grinding mill is typically composed of a main unit, classifier, blower, bucket elevator, electromagnetic vibrating feeder, storage hopper, and other components. The main unit of the mill is usually equipped with a high-pressure spring, which provides the necessary pressure for grinding materials. The classifier is used to control the particle size distribution of the final product.

In summary, the barite ultrafine powder grinding mill is a specialized equipment for grinding barite into ultrafine powder, which is widely used in various industries.

Barite ultrafine powder grinding mill advantages

The following are the advantages of using a barite ultrafine powder grinding mill:

High grinding efficiency: The grinding mill is designed to grind materials to ultrafine size, and it has a high grinding efficiency. This means that more material can be processed in a shorter amount of time, which can increase productivity.

Energy-saving: The grinding mill is designed with advanced technology that reduces energy consumption. This means that less energy is required to grind the same amount of material, which can reduce operating costs.

Environmental protection: The grinding mill is designed to reduce dust and noise pollution during the grinding process. This means that it is environmentally friendly and can help companies meet environmental regulations.

Wide range of applications: The grinding mill can be used to grind various materials, including barite, limestone, dolomite, calcite, and other minerals. This means that it is versatile and can be used in various industries.

High product quality: The grinding mill produces ultrafine powder with a uniform particle size distribution. This means that the product quality is consistent, which is important in industries such as pharmaceuticals, where product consistency is critical.

Overall, a barite ultrafine powder grinding mill is a valuable investment for companies that need to process barite into ultrafine powder. Its advantages include high grinding efficiency, energy-saving, environmental protection, wide range of applications, and high product quality.

If you would like to know more about this, please click here and leave us a message with your specific requirements, and our sales manager will contact you later.

Scan the QR code to read on your phone

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40