The primary use of barite powder is as a weighting agent in drilling fluids used in oil and gas exploration and production.

What is the future market for barite powder?

What is the future market for barite powder?

Future market for barite powder

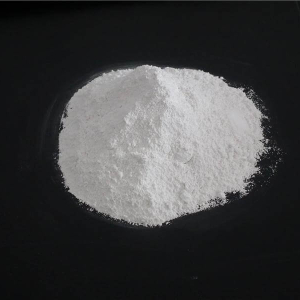

Barite powder is a mineral that is primarily used in the oil and gas industry as a weighting agent for drilling fluids. It is also used in the manufacturing of various industrial products, such as paint, rubber, and plastics. The demand for barite powder is expected to be driven by the growth in the oil and gas industry, as well as the increasing demand for industrial products.

According to a report by Grand View Research, the global barite market size was valued at USD 1.55 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 3.8% from 2021 to 2028. The report also suggests that the increasing demand for oil and gas, particularly in emerging economies, is expected to be a key driver of the market.

Another factor contributing to the growth of the barite powder market is the increasing use of barite in the medical industry. Barite is used in X-ray and CT scan machines as a contrast agent, which enhances the visibility of body tissues and organs.

Overall, the future market for barite powder is expected to grow, driven by the increasing demand from the oil and gas industry, the expanding use of barite in the medical industry, and the growing demand for industrial products that use barite as a raw material.

Processing flow of barite powder

The processing flow of barite powder typically involves crushing, grinding, classifying, drying, and packing several steps, which may vary depending on the specific characteristics of the raw material and the intended use of the final product.

Crushing: The raw barite material is usually first crushed to a suitable size by a jaw crusher or impact crusher.

Grinding: After the initial crushing, the crushed barite is further ground to a finer size using a Raymond mill, high-pressure grinding mill, or other grinding equipment.

Classifying: The ground barite particles are then classified according to their size using a classifier. This process separates the larger particles from the smaller ones.

Drying: If necessary, the classified barite particles may be dried in a rotary dryer or other drying equipment to remove any residual moisture.

Packing: The final step in the processing flow of barite powder is packing the product in bags or other containers for storage and transportation.

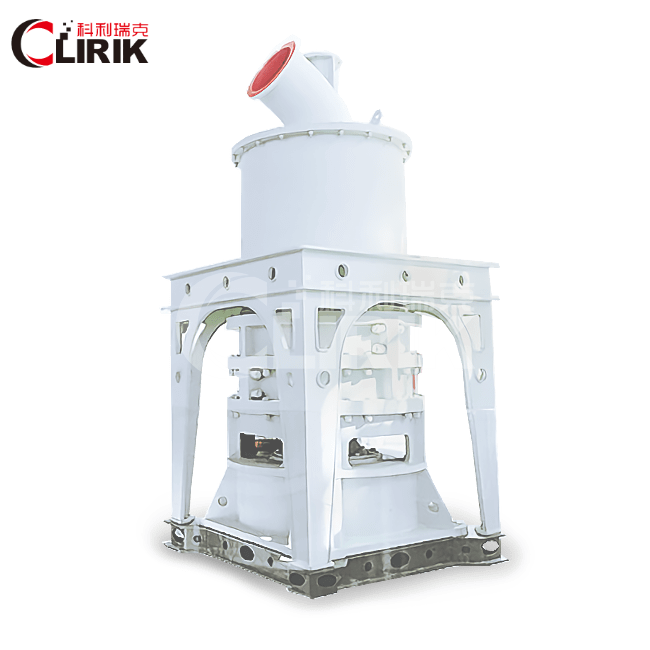

Processing machine of barite powder

SHANGHAI CLIRIK MACHINERY CO., LTD is specializing in research, manufacture and sales of all kinds of mining equipment.

Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Our products cover micro powder grinding mill, high pressure grinding mill, Europe an version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on.

Scan the QR code to read on your phone

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40