The primary use of barite powder is as a weighting agent in drilling fluids used in oil and gas exploration and production.

What is the working principle of barite superfine powder mill?

What is the working principle of barite superfine powder mill?

Working principle of barite superfine powder mill

Barite superfine powder mill is a grinding equipment designed to process barite into fine powder. The working principle of this mill is based on the grinding of materials between fixed and rotating grinding discs.

The barite material is fed into the mill through the feeding device, and the material is ground by the rotating grinding discs. The ground material is then collected in the dust collector, and the fine powder is separated from the coarse particles.

The grinding process is controlled by the airflow, which is generated by the fan. The airflow carries the ground material from the grinding chamber to the classifier. The classifier separates the fine powder from the coarse particles, and the fine powder is collected in the dust collector.

The barite superfine powder mill is equipped with a variety of advanced features, such as a high-speed rotating grinding disc, a high-pressure airflow system, and a precise control system. These features allow the mill to produce a fine powder with a high degree of uniformity and consistency.

In summary, the working principle of barite superfine powder mill is based on the grinding of materials between fixed and rotating grinding discs, which is controlled by the airflow and the precise control system. This process produces a fine powder with a high degree of uniformity and consistency.

Product advantage of barite superfine powder mill

Barite superfine powder mill is a type of grinding equipment that is designed to process fine and ultrafine powder of barite minerals. Here are some of its advantages:

High Efficiency

Barite superfine powder mill has a high efficiency and low energy consumption. The milling process is stable, and the product quality is good. It can effectively improve the grinding efficiency and productivity of the milling process.

Wide Range of Applications

The barite superfine powder mill can be used in various industries such as chemical, metallurgical, building materials, mining, and other fields. It is suitable for grinding materials with Mohs hardness below 7 and humidity within 6%, such as barite, calcite, marble, limestone, kaolin, and other non-metallic minerals.

High Precision

The equipment is equipped with a high-precision grading system, which can produce products with a particle size of 325-2500 mesh. The finished product has a high precision and uniformity, which can meet the requirements of different industries.

Environmental Protection

Barite superfine powder mill adopts a pulse dust collector and muffler to reduce dust pollution and noise. It can effectively reduce the harm to the environment and the health of workers.

Easy Maintenance

The equipment has a simple and compact structure, which is easy to maintain and repair. The wearing parts are made of high-quality wear-resistant materials, which can prolong the service life of the equipment and reduce the maintenance cost.

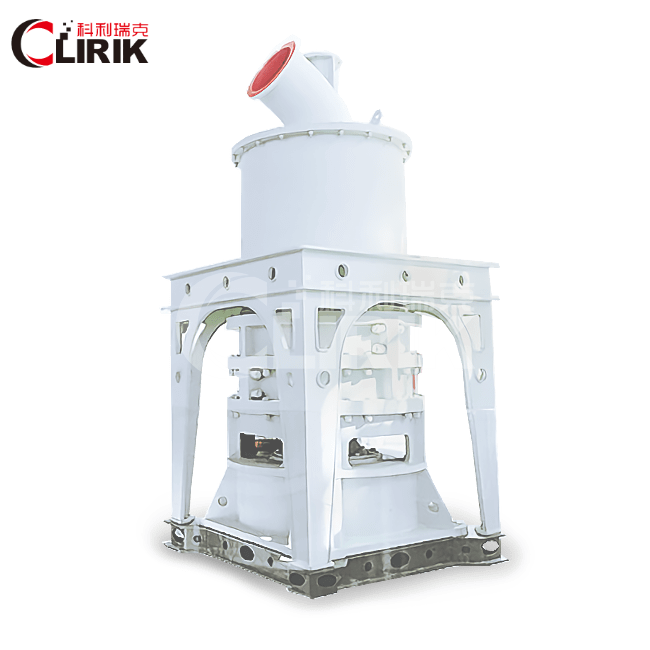

Barite Powder Ultrafine Grinding Mill

Model: HGM series

Brand: Clirik

Powder Fineness Process Ability: 325-3000 mesh

Capacity: 0.5-45 t/h

Use Range: Barite, Gypsum, Calcite, Calcium Carbonate, Dolomite,Carbon Black, Kaolin, Marble…

Application: Mining, Chemiscal, Transport And Many Other Different Areas

Overall, the barite superfine powder mill has many advantages, which make it an ideal equipment for processing barite minerals and other non-metallic minerals.

More products

In addition to HGM series of barite superfine grinding mill, Clirik can also provide you with other series of barite superfine grinding mill machines.

Such as: CLUM series barite powder ultrafine vertical roller mill, YGM series barite powder high pressure suspension grinding mill, CLRM series barite powder enhanced roller grinding mill and so on.

Scan the QR code to read on your phone

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40