The primary use of barite powder is as a weighting agent in drilling fluids used in oil and gas exploration and production.

Which Should You Choose Barite Grinding Mills?

Which Should You Choose Barite Grinding Mills?

Table of Contents

The prospect of barite

Barite or Baryte, is the mineral consisting of barium sulfate and is typically white or colorless.

In addition to its use as a weighting agent in drilling muds, barite has a variety of other uses for the crystallized mineral as well, including:Used in paint as a filler to regulate the thickness and increase the stability of the paint and brightness of its color Inserted between paper fibers for playing cards for higher density Used as a weighting filler in rubber mud flaps and other rubber materials that require extra weight X-ray shielding agent for medical purposes ,as a result,its market is growing.

According to the report made by FMI, the global barite market size is estimated to be worth around US$1.46 Bn in 2022, and the overall market is projected to grow at a moderate CAGR of 4.0% between 2022 and 2030, totaling US$2.0 Bn by 2030.

Among various barite products, barite powder is expected to dominate the market during the forecast period.This boosts the demand for barite grinding mills.

Recommend of barite grinding mills

Barite grinding is generally divided into four types, namely, coarse powder processing (≤80 mesh), fine powder processing (80 mesh-400 mesh), ultra-fine powder processing (200 mesh-2500mesh), and micro powder processing (400mesh-3000 mesh). It can be seen that the fineness of barite powder is an important consideration in choosing a barite mill. Commonly used barite grinding mills are European Coarse Powder Grinding Mill, Raymond mill, micro powder grinding mill and ultrafine vertical roller mill.

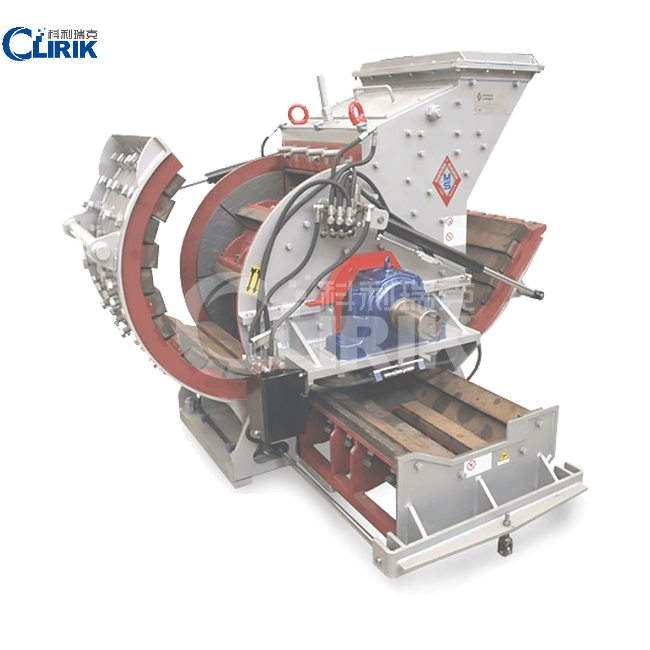

Recommend Product 1

Barite Powder European Coarse Powder Grinding Mill

Advantage : 1.The flow rate of European coarse grinding mill is steady and the output is substantial. The production capacity is 100 t/h.

2.European coarse powder grinding mill can grind water powder content in 15% of the material.

3.The European coarse powder grinding mill adopts vertical structure, simple shape and easy maintenance.

Disadvantage : 1.The fineness of the European coarse powder grinding mill fineness is limited.

2.The bearing room temperature shall not exceed 50℃ when the main engine of European coarse powder grinding mill is running.

Recommend Product 2

Barite Powder Raymond Mill

Advantage : 1.Barite powder Raymond mill cost is not high, reducing the investment cost.

2.Barite powder Raymond mill has a compact structure and a smaller footprint. Low requirements on the installation site and strong adaptability.

3.Barite powder Raymond grinding powder fineness uniformity, screening rate up to 99%.

4.The application of Barite powder Raymond grinding pulse bag filter and muffler greatly reduces dust pollution and noise, so that the grinding system is more environmentally friendly.

5.Raymond mill has its own powder selection system, the fineness can be adjusted in 80-400 mesh.

Disadvantage : 1.Barite powder Raymond mill after long-term use of RAYMOND MILL, the parts of the equipment wear out, and coarse powder is easy to appear.

2.Barite powder Raymond mill Equipment parts need to be replaced after long-term use, which increases the maintenance cost.

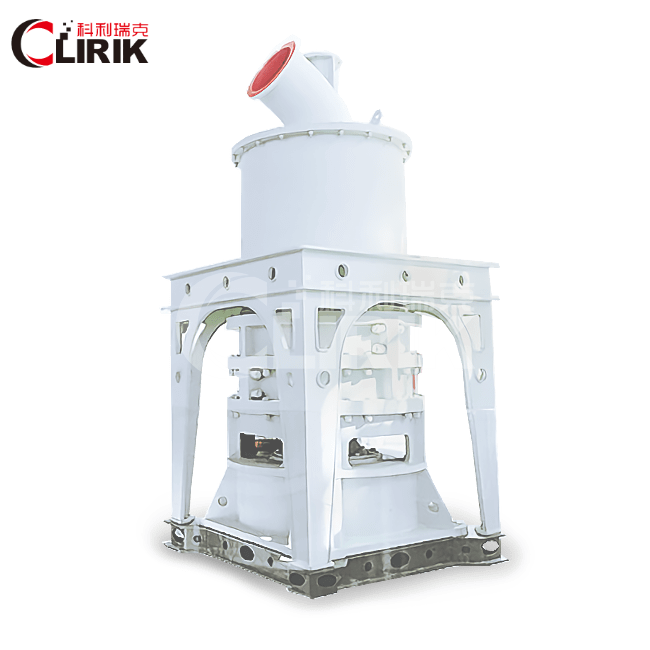

Recommend Product 3

Barite Powder Micro Powder Gridning Mill

Advantage : 1.Barite Powder Micro Powder Gridning Mill Wearing parts are made of wear-resistant materials. High utilization rate of Wear material: 2-5years.

2.Barite Powder Micro Powder Gridning Mill Multi-layer grinding ring design for higher grinding efficiency.

3.Barite Powder Micro Powder Gridning Mill Wide grinding range. Adjustable particle size: 200-2500 mesh.

4.Barite Powder ultrafine Powder Gridning Mill The structure is firm and reliable. The design of the mill is rigorous, so no screw loosening to damage the machine.

5.Barite powder micro gridning mill The operation of intelligent control system is more convenient.

Disadvantage : 1.The micro powder grinding mill can only control the noise and dust in a certain range in the milling production, and has not completely realized the noise-free and dust-free production process, which will still produce certain pollution to the environment.

2.Barite Powder micro powder mill Large material can not be broken directly. It must be broken by jaw or hammer before grinding.

Recommend Product 4

Barite Powder ultrafine vertical roller mill

Advantage : 1.Barite Powder ultrafine vertical roller mill is easier to form material layer than ordinary vertical mill, so that the mill can grind to the required fineness at one time.

2.Barite Powder ultrafine vertical roller mill Multi-head grading machine, no secondary air separation classification, no inferior materials.

3.Precompaction device of material layer, small vibration of ultra-fine vertical mill, effective development of power.

4.Pump suction lubrication can not only fully lubricate and cool roller bearings, but also ensure that there will not be too much oil stored in the roller bearing room and lead to leakage.

5.Barite Powder ultrafine vertical grinding mill Intelligent roller pressure control to avoid destructive impact and violent vibration.

Disadvantage : 1.Barite Powder ultrafine vertical grinding mill high investment cost.

2. Barite Powder ultrafine vertical roller mill Large material can not be broken directly. It must be broken by jaw or hammer before grinding.

Customer case

The following pictures are the field pictures of our customers in the past. If you want to know more information about products or related cases, you can leave us your contact information by email or Whatsapp. Our sales manager will contact you later and send you a detailed list of products, cases analysis and quotations.

Scan the QR code to read on your phone

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40